SPECIALIZING IN

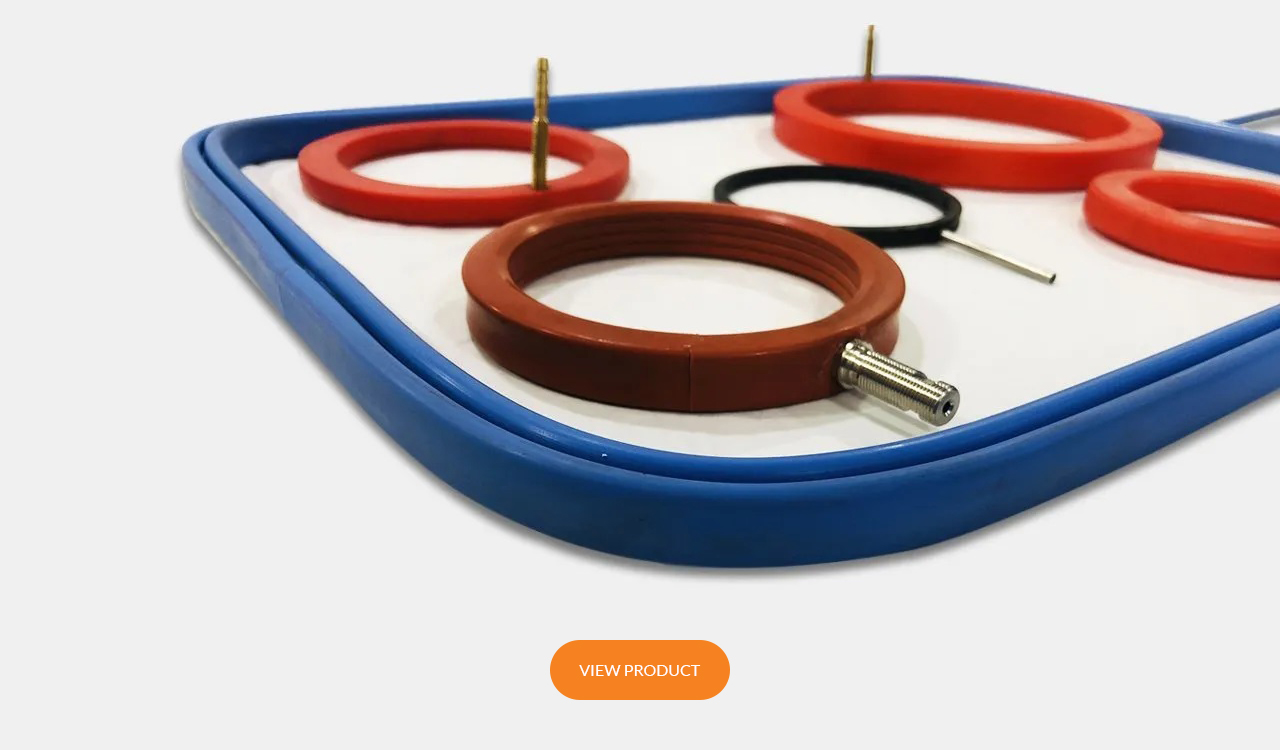

Inflatable Seals

SINCE 1972

SPECIALIZING IN

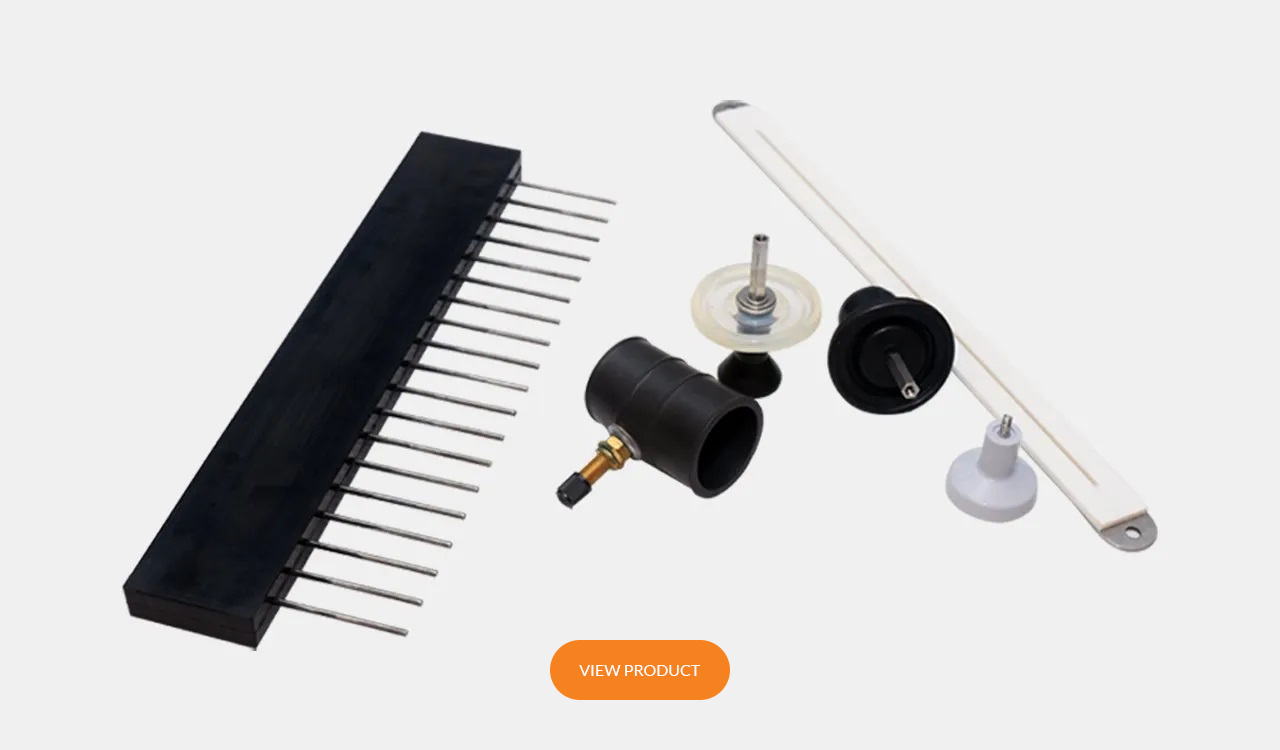

Rubber Extrusions

SINCE 1972

HL3 Certified for Fire Safety

Rubber Diaphragms

for extreme conditions

Molds

0

+

Years in Business

0

+

Employees

0

+

On Time Delivery

0

%

Who we are

About us

Established in 1972, Western Rubbers specializes in manufacturing rubber diaphragms, rubber extrusions and inflatable seals. With over 50 years of experience, our seals are made up of elastomers having specially developed in-house formulations, which make our seals not only appealing in aesthetics but also long lasting in extreme environments. We take pride in extruding intricate shapes and designs, which have otherwise been difficult to manufacture. We guide and work with our clients to meet their stringent parameters on compression set, elongation, hardness, density and other such physical as well as chemical properties which are required in their application.

Watch Video

Sneak Peak into Western Rubbers - Company Introduction Video

Why Choose Us

OUR BENEFITS

2500 extrusion dies

Profiles up to 5 inch in diameter can be extruded

In-house tool development

Diaphragm sizes range from 1/4″ to 55″ diameter

Clients Love us

Our Clients

ALL INDUSTRIES

CRITICAL DOORS

RAILWAYS

PUMPS & VALVES

FOOD AND PHARMA

Daily Updates

Our Blogs

Stay updated with the latest in rubber sealing, reference guides, important company & industry updates and much more with our blogs.