3 Ways to Extend the Life of Your Inflatable Seals by 2X

Are you constantly dealing with premature failures in your inflatable seals, leading to costly downtime and replacements?

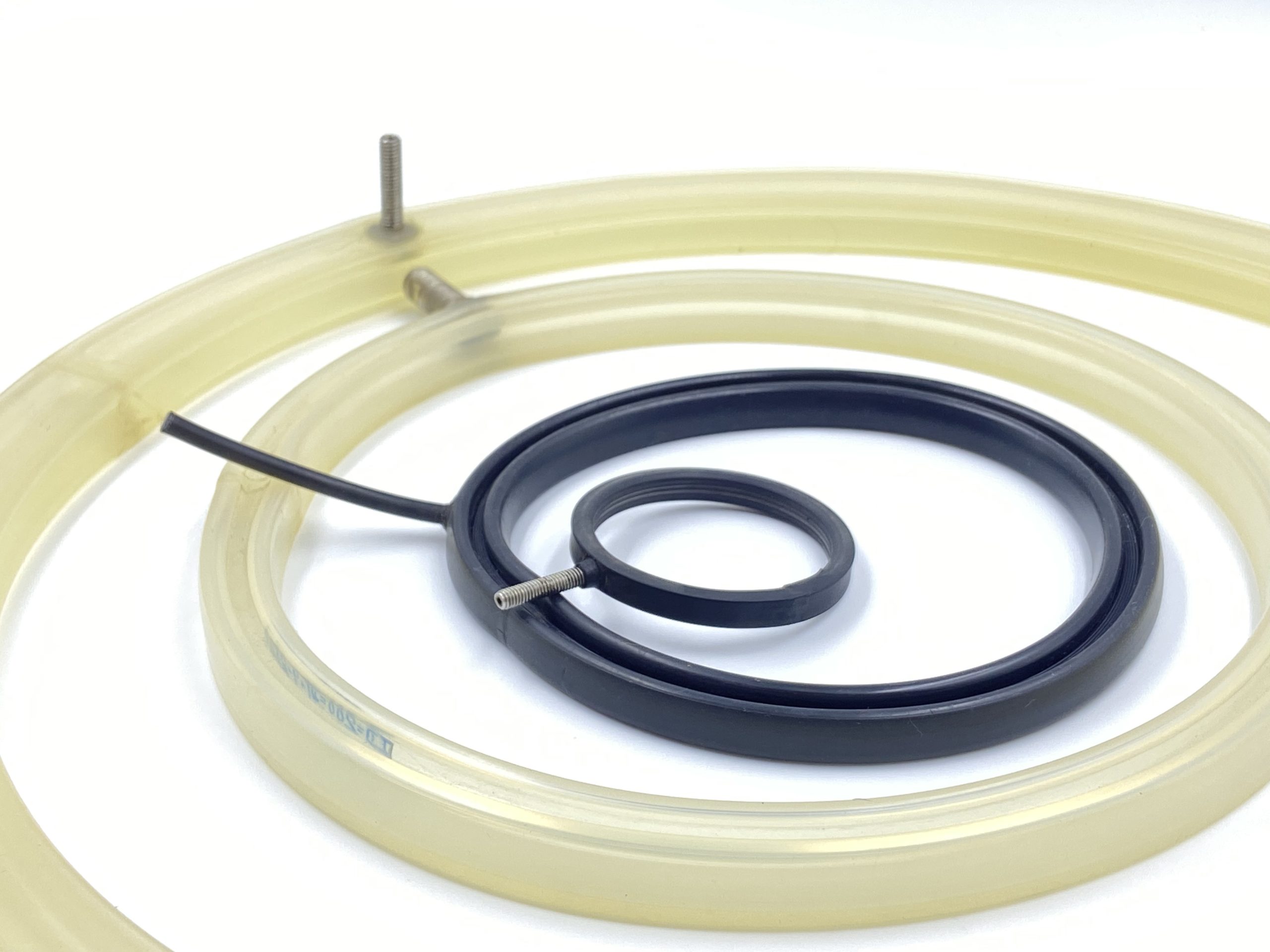

If you’re in industries like manufacturing, aerospace, or pharmaceuticals, you know how crucial these seals are for creating airtight barriers in doors, hatches, and machinery. But what if you could double their lifespan extending it by 2X with some smart strategies?

In this post, we’ll dive into three proven ways to make that happen. These tips aren’t just theory; they’re backed by expert insights and can save you time, money, and headaches. Let’s get into it!

Way 1: Choose the Right Material and Size from the Start

One of the biggest culprits behind short-lived inflatable seals is starting off on the wrong foot with mismatched materials or improper sizing. Think of it like buying shoes that are too tight or made from cheap fabric; they’ll wear out fast and cause blisters (or in this case, leaks).

To extend your seals’ life, prioritize selecting materials that match your application’s demands. For example, if your setup involves chemicals or high temperatures, opt for resistant compounds like fluorocarbon (FKM) instead of standard silicone.

Avoid common pitfalls like undersizing, which puts constant tension on the seal, or oversizing, which leads to poor fit and damage. Also, consider fabric-reinforced options for added strength and durability in high-pressure environments.

Pro Tip: Consult with a sealing expert during design to factor in gap width, pressure needs, and movement range. By getting this right, you can minimize wear from the get-go and potentially double the operational life turning a 2-year seal into a 4-year powerhouse.

Way 2: Master Proper Installation and Inflation Techniques

Ever inflated a balloon too much and watched it pop? The same principle applies to inflatable seals: overinflation or underinflation is a fast track to failure, causing uneven stress and reduced performance.

Improper installation, like wrong orientation or ignoring manufacturer guidelines, can also lead to immediate damage or leaks.

To combat this, always follow precise installation steps: Clean sealing surfaces thoroughly, use compatible tools to avoid scratches, and adhere to recommended tightening torques for even pressure. During operation, stick to the specified inflation pressure and never exceed it to prevent bursting or excessive wear.

Adding a retaining system can further protect the seal from external damage, prolonging its life in tough applications.

Engaging Anecdote: A factory saw seals fail every six months due to overinflation. After training the team on proper techniques, failures dropped by half effectively doubling seal lifespan. You can achieve the same by incorporating pressure monitors and routine checks into your workflow.

Way 3: Commit to Regular Maintenance and Optimal Conditions

Inflatable seals aren’t “set it and forget it” items; neglecting them is like skipping oil changes on your car; they’ll break down sooner than expected. Regular maintenance is key to spotting issues early and keeping things running smoothly.

Start with routine cleaning to remove dirt, residue, and debris that cause abrasion use mild cleansers and soft cloths, avoiding harsh chemicals. Apply compatible lubricants to reduce friction, and inspect for cracks, swelling, or discoloration during visual checks.

Optimize conditions by avoiding extreme temperatures, pressure spikes, UV exposure, and vibrations store spares in cool, dry, dark places to prevent premature aging.

Quick Checklist for Maintenance:

- Weekly: Clean and lubricate

- Monthly: Inspect for wear

- As Needed: Adjust for environmental changes

By making maintenance a habit, you can prevent buildup and stress that halve seal life, effectively doubling it through proactive care.

Wrapping It Up: Double Down on Durability

There you have three actionable ways to extend the life of your inflatable seals by 2X: smart material and sizing choices, flawless installation and inflation, and consistent maintenance under optimal conditions.

✅ Want to double the life of your seals? Start here:

📩 Submit your seal drawing for a free sizing check

🔍 Request our Seal Life Optimization Checklist

📞 Talk to a Western Rubbers engineer today

Let’s build reliability into your system.

👉 Contact Us ›

No comment yet, add your voice below!