5 Hidden Costs of Using the Wrong Inflatable Seal

Think all inflatable seals are the same? Discover how the wrong seal can cost your operation in downtime, repairs, and even failed audits.

⚠️ It’s Just a Seal… Until It’s Not

To many, it’s just rubber. But to engineers, that one seal can make or break a build. Especially when it fails under pressure quite literally.

The truth? A well-chosen seal protects your reputation, your timelines, and your budget. It’s not about buying a component, it’s about engineering confidence.

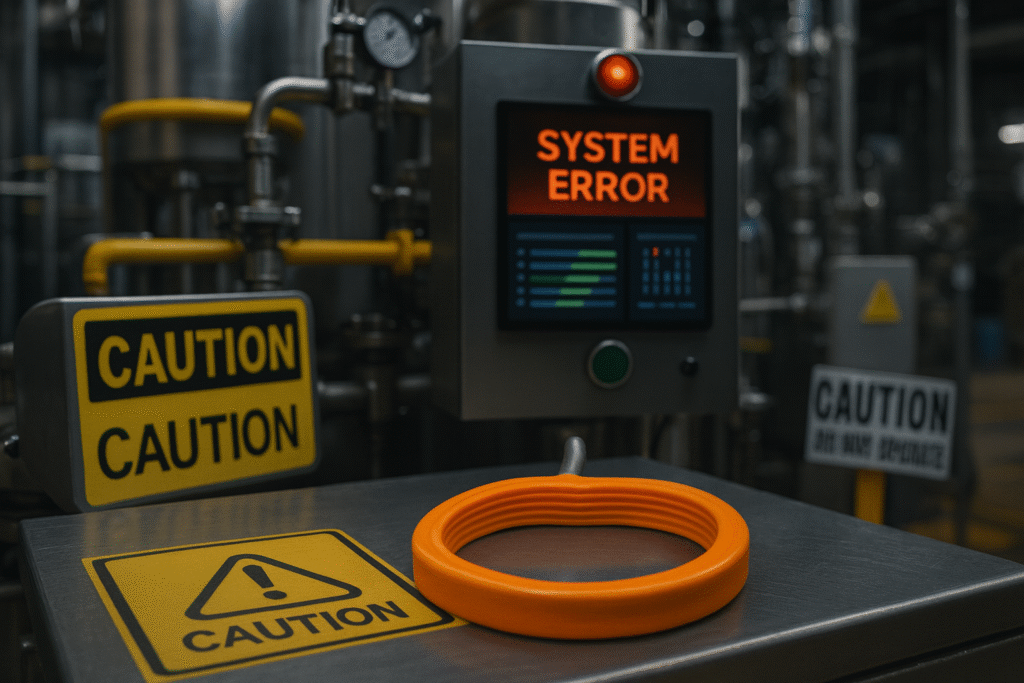

1. Seal Failure That Halts Production

When a poorly chosen inflatable seal bursts, warps, or leaks mid-operation, your entire workflow comes to a standstill.

“We lost an entire shift because the inflatable seal couldn’t hold vacuum pressure during a routine test.”

Sound familiar? One small failure. Full system halt. Alarms blare. Engineers scramble. And the backlog? It builds fast.

2. Frequent Seal Changes = Labor Drain

Some seals just aren’t built for the job especially in high-frequency systems. The result?

- Too many replacements

- Unexpected maintenance

- Lost hours on reordering and supervision

👷♂️ Say one change takes 45 minutes. Do it 10 times a month across 5 units you’ve lost almost 40 hours of skilled labor.

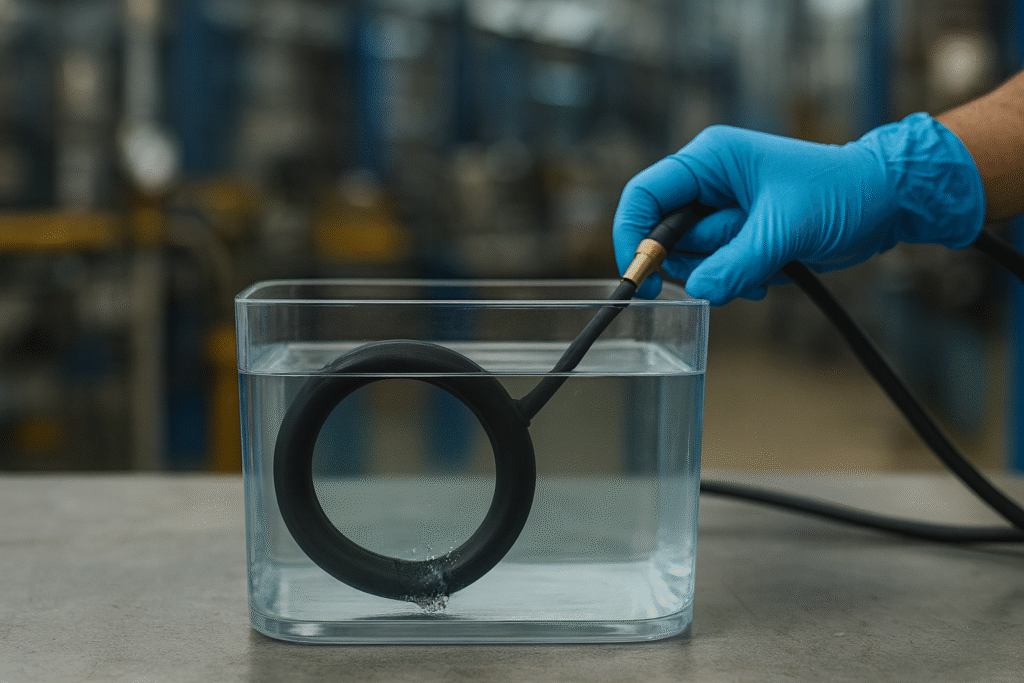

3. Failed Leak Tests & Validation Delays

Validation tests aren’t forgiving. Whether it’s a bubble during a leak test or material degradation during thermal cycling, a bad seal is hard to hide.

- It affects system validation

- Delays client handovers

- Impacts team confidence in the design

🔍 Is your current seal tested against your exact operating pressures, cleaning agents, and temperature fluctuations?

Hit the pressure point: Engineers want to pass validation on the first attempt not after 3 retests.

4. Safety Risks from Misfitted Seals

Think about what leaks into or out of your system. Hot gases, reactive chemicals, or even compressed air escaping at the wrong time puts operators and bystanders at risk.

And if the seal inflates unevenly, bends under mounting stress, or rotates in the groove the issue multiplies.

Engineer fear: Being held responsible for a near-miss or worse, a reportable safety event.

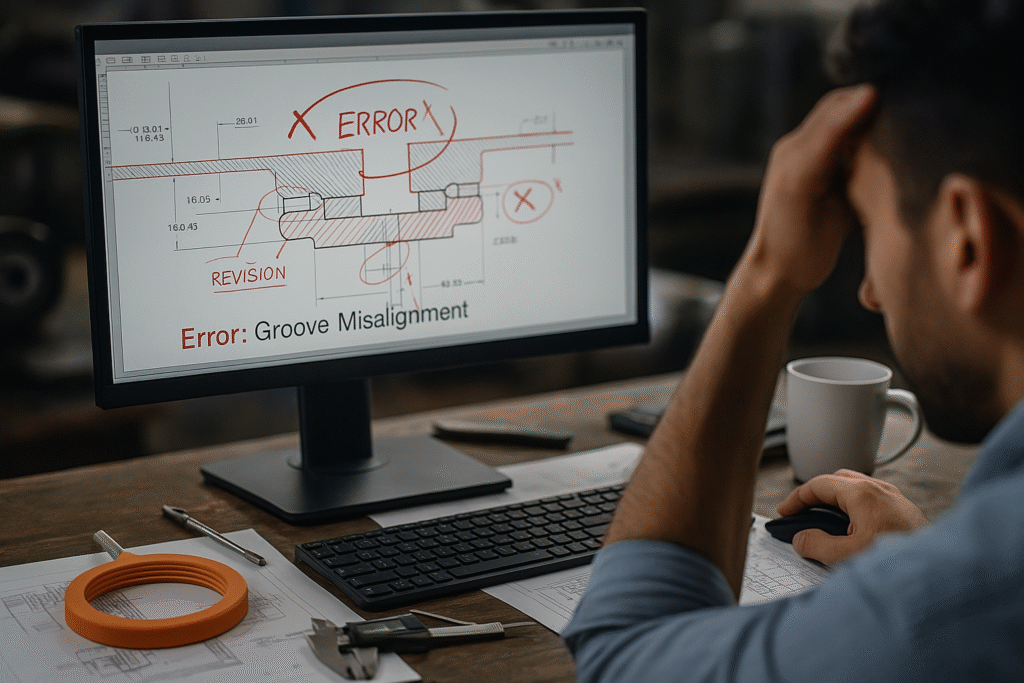

5.Redesign Costs from Seal Misalignment

Let’s say the seal doesn’t seat properly. Or inflates beyond expected range. That means:

- CAD revisions

- Groove redesigns

- New mold charges

And worst of all delayed timelines. What should’ve been a seal decision becomes a full system redesign.

Real engineer value: Designing it once and never having to rethink it again.

Cost Impact Snapshot: Wrong Seal = Right Problem

Design Flaw | Actual Result | Recovery Cost Estimate |

|---|---|---|

Overinflated seal | Mid-cycle failure, damage | Downtime + test failure |

Poor groove fit | Seal rotates or leaks | Redesign cost + delays |

No internal reinforcement | Frequent fatigue & burst | 3–5x seal replacements |

Incorrect material | Degraded under solvents/temp | Retesting + cleaning |

Underspected inflation | Pressure mismatch | Performance loss + retry |

🎯 Choose Performance Over Price Tag

Instead of asking:

🧾 “How much does the seal cost?”

Ask:

✅ How many cycles will it last under actual use?

✅ Will it hold up under my process cleaning or thermal conditions?

✅ Can it withstand 24×7 actuation, pressure swings, or misalignment?

A ₹1,000 mistake can ripple into a ₹10L delay and land on your desk. Why risk a design that won’t hold up under pressure?

🔧 Where Western Rubbers Adds the Edge

We don’t just supply seals, we engineer peace of mind. Here’s what working with us gets you:

🧩 Tailored inflatable seals that match your groove, pressure & motion

🦾 Reinforced options to handle 2+ bar, SIP/VHP, or continuous duty

🔬 Custom extrusions engineered for lifecycle and performance

📩 Have a drawing or spec? Let’s walk through it together engineer-to-engineer.

📈 Explore Custom Sealing Solutions →

🧪 See Real-World Savings in This Case Study →

Let’s Cut 5 Weeks Off Your Project Timeline

Don’t let a ₹1,000 mistake cost you ₹10 lakhs. Why spend 13 weeks troubleshooting when we deliver in 8?

🚀 Engineer with confidence. Avoid the guesswork. Seal it right the first time.

No comment yet, add your voice below!