Why Inflatable Seals Fail After Autoclave & SIP Cycles in Pharma Equipment

Many inflatable seals don’t fail on day one. They fail after the fifth autoclave cycle, or the twentieth SIP run, or halfway through PQ when everything should be stable.

On paper, the seal material is compliant. In practice, sealing performance slowly degrades. This article explains why inflatable seals fail after autoclave and SIP cycles, what actually changes inside the seal over time, and how engineers can design and specify seals that survive real pharmaceutical sterilization conditions.

Sterilization Changes the Seal, Not Just the Environment

Autoclave and SIP cycles expose inflatable seals to high temperature, saturated steam, pressure fluctuations, and repeated thermal expansion and contraction. While the seal may look visually intact, its mechanical behavior changes with every cycle.

Validation failures happen when these changes were never anticipated, tested, or documented.

Heat Accelerates Compression Set Quietly

Compression set is one of the most misunderstood failure modes in inflatable seals. During sterilization, elastomers soften at elevated temperatures, molecular chains rearrange under compression, and the seal doesn’t fully recover after deflation.

Over time, this leads to reduced sealing force, slower inflation response, and uneven contact pressure. Engineers often discover this when pressure decay tests start failing, higher inflation pressure is suddenly required, or leaks appear intermittently rather than consistently.

From a validation standpoint, this raises a critical question: Is this seal still performing as originally qualified?

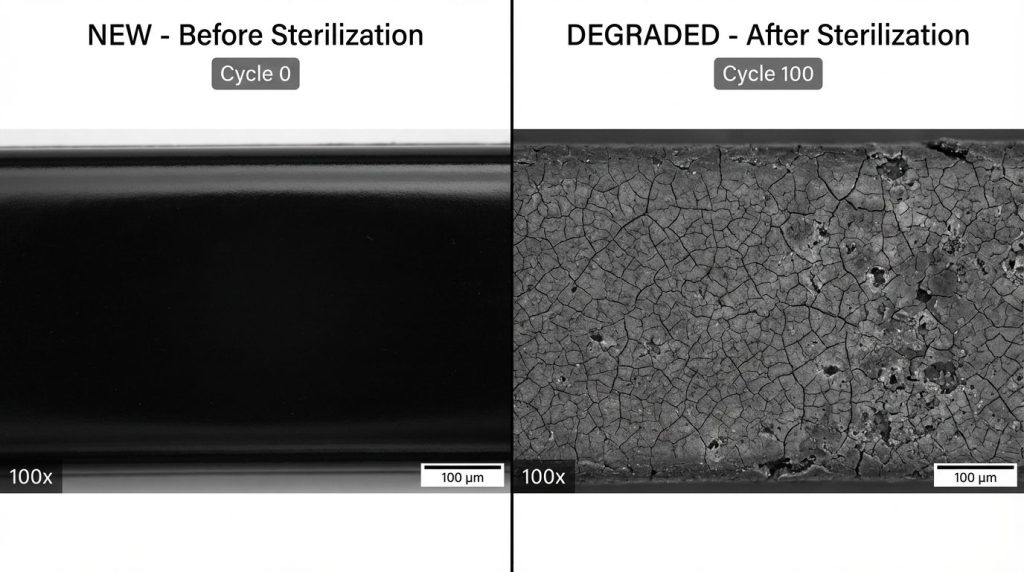

Steam Exposure Alters Material Properties Over Time

Steam isn’t neutral to elastomers. Repeated autoclave or SIP exposure can cause material hardening, surface micro-cracking, loss of elasticity, and changes in durometer. These effects are gradual and often invisible during routine inspection.

A common mistake is assuming a material rated for high temperature is automatically suitable for repeated steam sterilization. In reality, temperature resistance doesn’t equal steam resistance over the seal’s lifetime.

Thermal Cycling Creates Stress at the Worst Locations

Inflatable seals expand and contract with temperature changes. During autoclave cycles, the seal expands faster than the groove, tensile stress increases at corners and joints, and bonded or spliced areas experience repeated strain.

After multiple cycles, this can lead to local thinning, weak points along the seal circumference, and unpredictable failure locations. These failures are difficult to explain during validation if no cycle-based testing data exists or stress points were never evaluated in design.

Over-Inflation Becomes a Hidden Risk After Sterilization

A common response to post-sterilization leakage is to increase the inflation pressure. While this may temporarily restore sealing, it introduces new problems: excessive tensile stress on a heat-aged seal, accelerated fatigue, and increased risk of rupture or bulging.

More importantly, it creates a validation inconsistency. Which pressure was validated? Which pressure is now being used? Any undocumented adjustment becomes a compliance risk.

Autoclave Cycles Expose Weak Documentation

Many inflatable seals fail validation not because they degrade, but because their degradation was never defined. Common documentation gaps include no specified maximum sterilization cycles, no post-SIP performance criteria, no cycle-life testing data, and no replacement threshold guidance.

During audits, the question becomes: How do you know when this seal is no longer acceptable? If the answer is subjective, validation confidence drops.

SIP Conditions Are Often Misrepresented in Testing

SIP conditions vary widely in temperature, dwell time, pressure, and ramp rates. Yet seal testing is often based on generic temperature ratings, short-duration lab tests, and non-representative cycles.

When real SIP conditions exceed tested assumptions, seal behavior changes faster than expected. This gap between tested conditions and real conditions is a frequent root cause of mid-validation failures.

How Engineers Can Prevent Autoclave and SIP-Related Seal Failures

Sterilization-related failures are preventable if addressed early. Best practices include specifying sterilization conditions during seal selection, validating seal performance across realistic cycle counts, defining maximum inflation pressure limits post-sterilization, documenting expected seal behavior over life, and aligning replacement intervals with cycle exposure rather than calendar time.

Most importantly, treat sterilization as a life-cycle event, not a one-time test.

The Bottom Line

Autoclave and SIP cycles don’t cause inflatable seal failures. They reveal weak assumptions. When material behavior, pressure limits, and life expectancy are clearly defined and documented, inflatable seals perform reliably even under aggressive sterilization regimes.

In pharmaceutical validation, it’s not enough for a seal to survive sterilization. It must remain predictable, traceable, and defendable, cycle after cycle.

No comment yet, add your voice below!