Boost Inflatable Seal Life Cycles by 100%: 4 Strategies for OEM Engineers

If you’re an OEM engineer, you know the frustration all too well when a well-designed piece of equipment suddenly goes offline because an inflatable seal failed far sooner than expected. It’s not just the replacement cost that stings; it’s the downtime, the production delays, and the constant worry that the next seal might fail too.

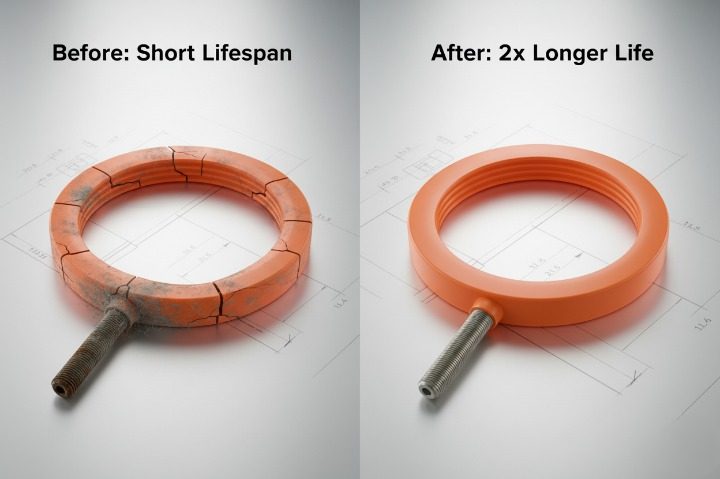

Now imagine doubling that seal’s service life. Whether it’s an inflatable silicone seal on a pharmaceutical isolator door or a heavy-duty inflatable gasket on a semiconductor tool, that kind of reliability can transform how your system performs. It reduces maintenance costs, increases uptime, and gives your designs a real competitive edge.

The good news? Achieving this isn’t rocket science, it’s the result of a few deliberate design, installation, and maintenance decisions. After decades of working with global OEMs as a trusted inflatable seals manufacturer, we’ve identified four proven strategies that can extend seal life by up to 100%.

1. Choose the Right Material and Reinforcement From the Start

The journey to long-lasting inflatable seals begins before a single part is installed; it starts with material selection. Most premature failures aren’t caused by bad design; they happen because the elastomer wasn’t matched to the application environment.

For many industrial applications, EPDM inflatable seals strike an excellent balance of cost, chemical resistance, and durability. But if you’re dealing with harsh or highly specialized conditions such as sub-zero environments, pharmaceutical processes, or corrosive media, inflatable silicone seals become the ideal choice. Their flexibility at extreme temperatures and compatibility with a range of media significantly improve performance.

And if your application involves frequent cycling, reinforcement is key. Adding fabric layers to the seal structure transforms a standard product into a high-cycle workhorse capable of thousands of inflations without cracking. In short, matching the material and reinforcement precisely to your environment is one of the most impactful ways to double your inflatable gasket lifespan.

2. Control Inflation for Consistent, Reliable Performance

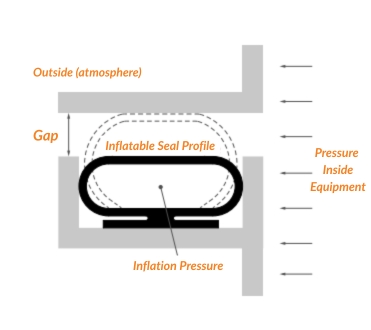

Even the best-engineered inflatable seals can fail prematurely if inflation isn’t managed correctly. Rapid pressurization introduces unnecessary heat and stress, quietly wearing down the elastomer long before its time.

A controlled approach makes all the difference. Increasing pressure in gradual increments allows the seal to expand evenly without over-stressing the material. Sticking to recommended pressure ranges around 2 bar for non-reinforced seals and up to 12 bar for fabric-reinforced ones helps prevent bursting and fatigue. Modern systems equipped with regulators, relief valves, and sensors can automate this process, ensuring consistent operation over thousands of cycles.

By treating inflation as a precision process rather than a simple on-off function, you significantly improve the reliability and lifespan of both standard and inflatable silicone seals.

3. Treat Installation as a Critical Engineering Step

A surprising number of seal failures happen not because of design flaws, but because of installation mistakes. Even a tiny nick from a sharp tool or a slightly misaligned groove can become a stress concentrator, dramatically reducing the life of the seal.

Proper installation starts with attention to detail. Make sure groove surfaces are smooth (Ra < 1) to minimize friction and wear. Keep inflation gaps tight ideally between 4 mm and 5 mm to reduce expansion stress. And always use blunt tools or hand-install the seal to avoid accidental damage. Crucially, ensure the system is fully closed before pressurizing; exposed seals under pressure are prone to rupture.

Working closely with your inflatable seals manufacturer for installation guidelines and best practices is an investment that pays off. Many OEMs report a 30–50% increase in seal life simply by refining their installation process.

4. Shift to Proactive Maintenance and Inspection

The final strategy is also the most overlooked. Many Inflatable Seals fail not because of poor design or installation, but because no one was watching. Reactive maintenance replacing seals only after failure guarantees unplanned downtime.

Instead, adopt a proactive maintenance schedule. Regular inspections can catch early warning signs such as micro-tears, UV damage, or hardening before they become critical. Cleaning the seal to remove debris and applying protective oils preserves elasticity, while thoughtful system design can shield seals from direct sunlight or aggressive chemicals. Most importantly, base replacements on real usage data like cycle counts and pressure histories instead of arbitrary time intervals.

A proactive approach turns maintenance from a cost center into a performance advantage, dramatically increasing reliability and extending seal service life.

Final Thoughts

Doubling the lifespan of your inflatable seals isn’t about luck, it’s about engineering discipline. From material choice and inflation control to installation precision and proactive maintenance, every decision plays a role in how well your system performs. Each small improvement compounds, leading to seals that last longer, fail less, and keep your equipment running at peak efficiency.

In industries where uptime is revenue, every additional cycle counts. And by applying these four strategies, you’re not just extending the life of an inflatable gasket, you’re building a system that delivers consistent, reliable performance for years to come.

💡 Next Step: Download our free Inflatable Seal Catalogue to explore detailed material comparisons, installation tips, and engineering best practices from a leading inflatable seals manufacturer.

No comment yet, add your voice below!