Cost-Effective Sealing Solution for a Space Research Organization’s Reverberation Chamber

Client Overview

A prominent space research organization based in Bangalore required an advanced sealing solution for a critical testing facility, a reverberation chamber used for rigorous sound, vibration, and pressure tests on satellites. The facility’s massive 120-tonne sliding door posed a unique challenge, demanding a precise and reliable seal to maintain the integrity of the testing environment.

Challenges

High Costs from Overseas Vendors

The organization initially sought quotes from international vendors for a custom inflatable seal. These quotes reached 8-digit figures, significantly increasing project costs and straining budgets.

Complex Technical Requirements

The sealing solution needed to meet highly specific and demanding criteria:

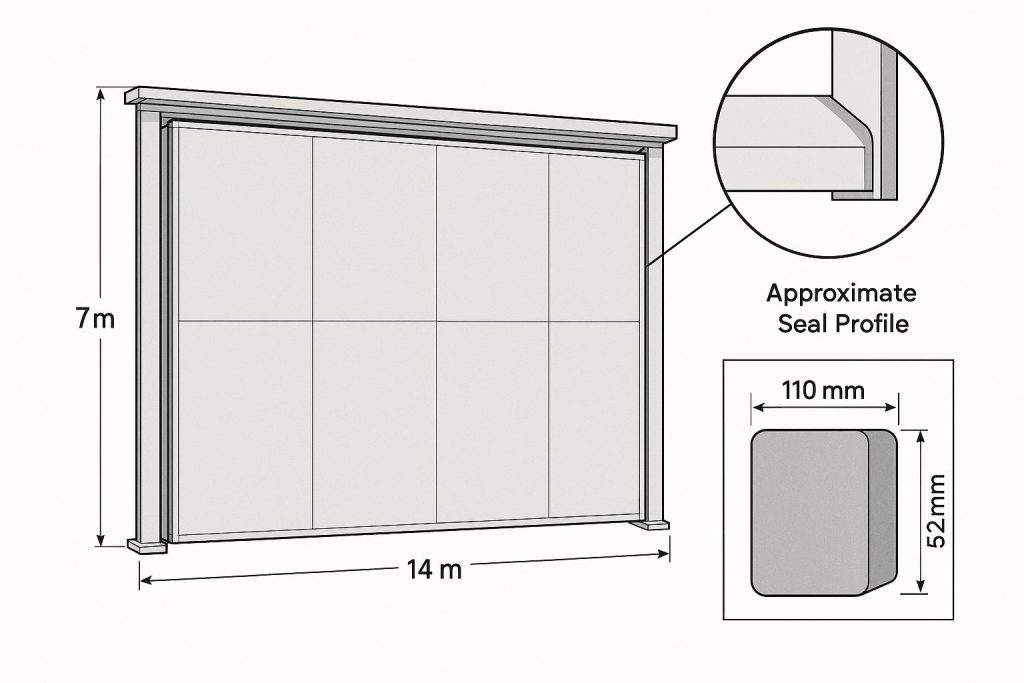

- Door Dimensions: The seal had to fit a door approximately 14m x 7m, including precise sealing for 90-degree corners.

- Seal Profile: Custom dimensions of 110 mm x 52 mm (width x height) with a total weight of 120 kg.

- Environmental Durability: The seal had to withstand extreme conditions, including high pressure and vibrations, during satellite testing.

Installation Complexity

Due to the seal’s size, weight, and critical application, on-site installation required skilled engineers to ensure precision and functionality in a high-stakes environment.

Western Rubbers’ Solution

Cost-Effective Engineering

Western Rubbers designed and manufactured the custom inflatable seal at a 6-digit cost, delivering substantial savings compared to the 8-digit quotes from overseas vendors. This was achieved through:

- In-House Expertise: Leveraging specialized engineering knowledge to design a high-performance seal.

- Local Material Sourcing: Utilizing high-quality, locally sourced materials to reduce costs without compromising quality.

- Precision Manufacturing: Employing advanced techniques to meet exact specifications.

Customized Seal Design

Western Rubbers developed a tailored inflatable seal that met the organization’s stringent requirements:

- Airtight Performance: Ensured a perfect seal for the 120-tonne sliding door, maintaining the chamber’s testing environment.

- Durability: Engineered with advanced materials to withstand extreme conditions, including high pressure and vibrations.

- Precision Fit: Designed to accommodate the door’s large dimensions and complex 90-degree corners.

On-Site Installation Support

A dedicated team of two Western Rubbers engineers traveled to the organization’s Bangalore facility to manage the installation process. The intricate installation, which required meticulous attention to detail, was completed over 6 days, ensuring optimal performance and alignment with the facility’s operational needs.

Results

Significant Cost Savings

By partnering with Western Rubbers, the organization saved millions of rupees compared to overseas vendor options. This cost efficiency allowed the organization to allocate resources to other critical initiatives.

Optimal Performance

The inflatable seal successfully maintained the reverberation chamber’s integrity, enabling reliable and accurate satellite testing. The seal’s robust design ensured consistent performance under extreme conditions.

Customer Satisfaction

The organization expressed high satisfaction with Western Rubbers’ ability to deliver a high-quality, cost-effective solution. The seamless on-site support and precision installation further reinforced the success of the partnership.

Conclusion

Western Rubbers’ innovative approach to designing and delivering a custom inflatable seal addressed the space research organization’s complex technical and budgetary challenges. By combining cost-effective engineering, advanced materials, and expert installation, Western Rubbers provided a high-performance solution that met stringent requirements while achieving significant cost savings.

No comment yet, add your voice below!