Enhancing Performance for a Global Leader’s Vacuum Impregnation Machines

Overview:

A global leader in vacuum impregnation technology faced recurring issues with their existing seal solutions. Frequent seal tearing and prolonged lead times disrupted operations and impacted productivity. This case study delves into how Western Rubbers addressed these challenges by providing durable and efficient sealing solutions tailored to their needs.

The Challenge:

The company faced several operational hurdles due to the shortcomings of their existing seal solutions:

- Frequent Seal Tearing: The seals began tearing within just one month of usage,

leading to frequent replacements and machine downtime. - Operational Disruptions: Downtime caused by damaged seals significantly impacted

the efficiency of their vacuum impregnation machines. - Prolonged Lead Times: Long delivery times from their current vendors further strained

their production schedules, making it difficult to maintain operational continuity.

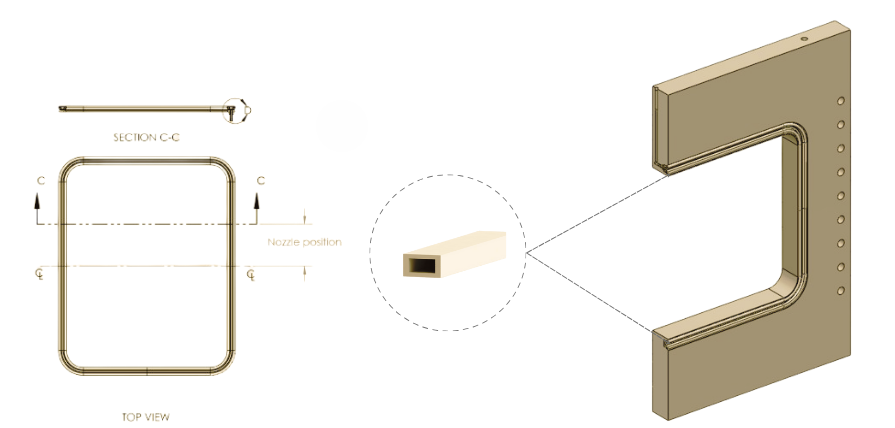

Western Rubbers’ Solution:

Upon identifying the issues, Western Rubbers proposed a robust solution:

- Fabric-Reinforced Seals: Seals reinforced with high-tear nylon were introduced, and

specifically engineered to withstand the demanding operating conditions of vacuum

impregnation machines. - Enhanced Longevity: The new seals exceeded expectations, lasting over a month

without any complaints, thereby reducing downtime and replacement frequency. - Optimized Production and Supply Chain: To address lead time challenges,

streamlined manufacturing and supply processes ensured timely delivery.

Results and Collaboration:

The successful implementation of the fabric-reinforced seals paved the way for further

collaboration:

- Product Development: Impressed with the performance, the company partnered with

us to design and develop an additional two types of seals for their machinery. - Continued Success: To date, Western Rubbers has supplied over 100 high-

performance fabric-reinforced seals, reinforcing their trust in our quality and reliability.

Impact: - Increased Operational Efficiency: The durable seals reduced downtime and minimized

the need for frequent replacements. - Improved Production Schedules: Timely delivery of seals resolved lead time concerns, aligning with their manufacturing goals.

- Cost Savings: Enhanced seal longevity translated to reduced maintenance and replacement costs.

Summary Table:

Parameter | Previous Vendor Seals | Western Rubbers Seals | Comparison (Advantage) |

|---|---|---|---|

Price (Saving) | 1x | 5x | 5x cost savings |

Seal Life (Months) | 1 | 6+ | 6x longer lifespan |

Delivery Lead Time

(Days)

| 56 | 28 | 2x faster delivery |

Conclusion:

Western Rubbers’ tailored solutions addressed the company’s challenges head-on, improving

the performance and reliability of their vacuum impregnation machines. This partnership

underscores our commitment to delivering high-quality, customized sealing solutions that drive

operational excellence for our clients.

No comment yet, add your voice below!