How to Avoid the Top 7 Sizing Mistakes When Specifying Inflatable Seals

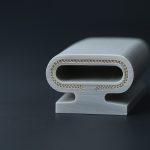

Inflatable seals are specialized rubber components that expand when filled with air, liquid, or gas to create airtight or watertight barriers. They’re widely used in industries like pharmaceuticals, aerospace, food processing, and manufacturing, where they provide reliable sealing for doors, hatches, and equipment.

However, improper sizing during specification can lead to leaks, premature failure, increased costs, and safety hazards. In this blog, we’ll explore the top 7 sizing mistakes engineers and designers often make and how to avoid them for optimal performance and longevity.

1. Specifying Incorrect Overall Dimensions

One of the most fundamental errors is choosing a seal that’s too small or too large for the application. A seal that’s undersized may remain under constant tension in its groove, leading to rapid wear and inadequate sealing. Conversely, an oversized seal might not fit properly, causing bunching, damage during installation, or inconsistent pressure distribution.

How to Avoid It:

- Measure the gap width, expected range of motion, and pressure requirements precisely.

- Use a detailed specifications checklist that includes overall active length, inflated height, and deflated profile.

- Consult with a reliable seal manufacturer early to ensure tolerances are correctly factored in.

2. Ignoring the Ideal Inflation Gap

Failing to specify the right inflation gap typically 4–5 mm for most seals can cause significant issues. A narrow gap complicates installation and risks damaging the seal, while a wide one leads to over-expansion, increased wear, and reduced operational life.

How to Avoid It:

- Design with the recommended inflation gap in mind.

- Test prototypes to verify the seal expands evenly without strain.

- For custom applications, match the gap to the seal’s cross-section and durometer.

3. Neglecting Groove Design and Surface Finish

Underspecifying the groove size or finish is a major issue. If the groove is too rough (e.g., Ra > 1.0 µm), it can abrade the seal. Incorrectly sized grooves can cause seals to slip or fail to seat properly.

How to Avoid It:

- Specify a groove Ra < 1.0 µm with no sharp edges.

- Use dovetail or undercut grooves for retention.

- Always refer to a proper groove design guide and avoid manual tool marks.

4. Overlooking Expansion Direction (ID, OD, or CL)

Not defining the expansion direction inward (ID), outward (OD), or radial (CL) can cause major alignment and fitment issues. This is especially common in circular or rectangular seals.

How to Avoid It:

- Define expansion type in early CAD models.

- Use molded corners for tight radii and U-shaped profiles.

- Reference the correct seal profile type during design review.

5. Insufficient Corner Radii in Non-Straight Seals

Seals with sharp corners or radii less than 4–8x the seal’s height tend to underinflate in bends. This results in dips or leaks.

How to Avoid It:

- Apply radii of 4× height (outward expansion) and 8× for inward.

- Add fillet pads or specify pre-molded corners.

- Build in 10–15% height margin to offset deflection.

6. Not Accounting for Pressure and Inflation Limits

Underestimating inflation pressure or specifying seals without pressure margin can cause deflation under dynamic loads.

How to Avoid It:

- Include pressure specs: duty cycle, expected PSI, safety factor (2–3x).

- For pressures above 2 bar, opt for fabric-reinforced inflatable seals.

- Use control valves and inflate gradually in 0.5 bar intervals during testing.

7. Failing to Check Fitment and Alignment Before Use

A seal that’s well-sized on paper can still fail in practice due to poor fitment or misalignment in the final assembly.

How to Avoid It:

- Test seal fitment in its actual groove with the system closed.

- Use retainers, clips, or adhesives for positioning.

- Always run a trial cycle before final installation, especially for FDA-compliant or ISO-critical environments.

🔍 Conclusion

Avoiding these top 7 sizing mistakes requires careful planning, accurate specifications, and real-world testing. Whether you’re sealing a cleanroom door, valve actuator, or aerospace hatch, the right fitment can make or break your system.

Seal It Once, Seal It Right

Don’t let a small miscalculation snowball into a full system redesign.

At Western Rubbers, we help engineers spec it right the first time from groove dimensions to FEA-verified profiles.

📩 Send us your drawing for a free fitment review or explore our inflatable seals.

Let’s eliminate seal sizing guesswork together.

No comment yet, add your voice below!