5 Pressure Handling Blunders That Can Pop Your Inflatable Seals (And How to Fix Them)

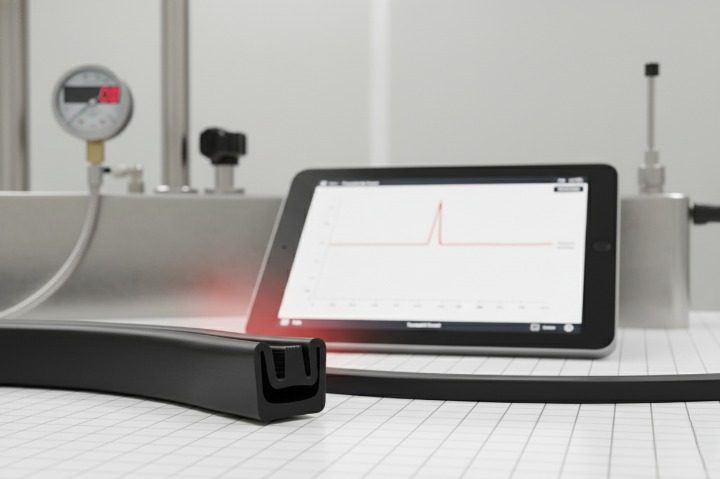

Picture this: You’re mid-operation maybe sealing a hydraulic test rig or locking down a containment chamber. Everything’s running perfectly, until… boom.

A seal bursts like a balloon at a birthday party. Fluids everywhere. Production halts. Maintenance scrambles. And someone quietly mutters, “pressure spike.”

Improper pressure handling is the silent killer behind most inflatable seal failures. The good news? Every one of these disasters is preventable.

Let’s break down the five biggest pressure mistakes and how to avoid turning your next seal into confetti.

1. Pushing the Pressure Envelope (a.k.a. Overloading Beyond Design Limits)

We’ve all been tempted to “just crank it up a notch.” But when it comes to inflatable seals, overpressure isn’t performance, it’s punishment.

Even a slight system spike can shove internal pressure past the seal’s rated limit. The fabric stretches, the elastomer thins out, and suddenly you’re picking fragments out of your groove.

Why it fails: The seal’s reinforcement and rubber can’t sustain the strain it tears under excessive tension.

Fix it before it fails:

- Calibrate your controls regularly. A quick pressure check before every run can save an expensive seal.

- Install relief valves. They vent excess pressure automatically, your first line of defense against runaway spikes.

- Stick to the specs. If your seal is rated for 100 psi, don’t flirt with 110. Ratings exist for a reason.

Pro tip: Treat your seal like a high-performance tire overinflate it, and it’ll blow when you least expect it.

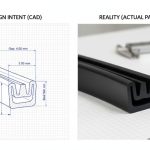

2. Inflating Outside the Groove (Testing Without Proper Support)

Inflating a seal outside its groove is like blowing up a balloon while holding it in midair it wobbles, bulges, and bursts unpredictably.

Without the groove’s support, there’s nothing to balance internal pressure, so expansion happens unevenly. Even “normal” inflation can turn deadly for the seal.

How to fix it:

- Never inflate outside the groove. Always test within the full assembly or a properly machined fixture.

- For bench tests, use a mock-up groove that mimics the actual installation geometry.

A seal needs its groove like a wheel needs a rim, no support, no control.

3. Rapid Cycling Chaos (Too Fast, Too Often, Too Fierce)

Pressure cycles are part of life. But rapid inflation/deflation cycles done at high speed or too frequently wear seals down faster than you think.

The constant expansion and contraction fatigue the rubber and reinforcement fabric, causing microcracks that grow with every cycle.

How to prevent fatigue:

- Use the right material. Reinforced inflatable seals handle high-cycle environments far better than standard solid profiles.

- Control ramp rates. Slow down inflation/deflation with programmable valves or flow regulators.

- Track your cycles. Add sensors or counters to replace seals before they reach their fatigue limit.

Consistency, not speed, keeps seals alive. Think marathon, not sprint.

4. Spike Surprise (Ignoring Pressure Transients)

Pressure spikes are sneaky; they don’t last long, but they hit hard. Start-ups, shutdowns, valve closures, or backflows can send short, violent bursts that no standard seal can absorb.

Why spikes sting: They exploit the weakest moment in your system right when pressure’s changing fast.

How to spike-proof your setup:

- Design with margin. Add 20–30% buffer above your max operating pressure.

- Add dampeners or accumulators. They absorb the shock, like suspension in a car.

- Monitor your data. Use pressure loggers to catch transient events and adjust your controls accordingly.

In one test case, simply adding dampeners reduced spike-related failures by 70%. That’s a lot fewer 3 a.m. maintenance calls.

5. Material Mismatch (or Ignoring Material Aging)

Even perfect pressure control can’t save you if the seal material itself can’t handle the environment.

Wrong compound = wrong behavior.

High heat? Rubber hardens and cracks.

Solvents? It swells.

Cold? It stiffens.

Over time, your “high-strength” seal becomes brittle and weak.

How to fix it:

- Choose environment-first. Cross-check pressure, temperature, and chemical compatibility before selecting material.

- Go reinforced for high pressure. Fabric layers like Kevlar or Nomex handle repetitive stress better than unreinforced seals.

- Inspect and replace proactively. Don’t wait for failure—schedule regular visual and leak checks.

Your seal’s compound is its armor. Pick the wrong one, and you’re fighting pressure with paper.

Wrapping It Up: Pressure Makes or Breaks the Seal

Inflatable seals are small components doing big jobs holding pressure, containing fluids, and maintaining safety. But when pressure is mismanaged, they’re the first to blow.

By avoiding these five pitfalls: overloading, groove skipping, rapid cycling, ignoring spikes, and poor material selection you’ll extend seal life, reduce downtime, and keep your systems airtight.

If you’ve ever had a seal fail mid-run, you know how expensive “just one mistake” can be. Spend the extra few minutes calibrating, checking, and logging pressure—it’s worth every second.

No comment yet, add your voice below!