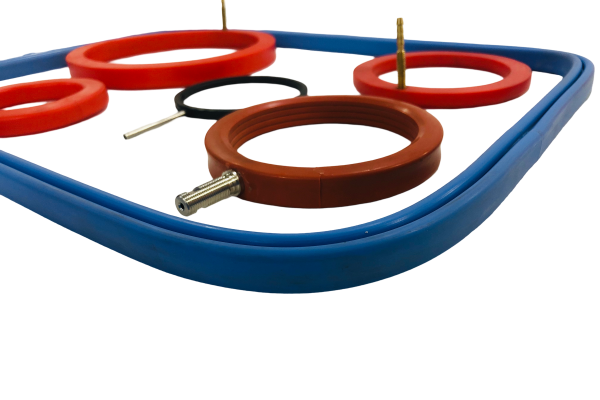

Precision-Engineered

Inflatable Seals

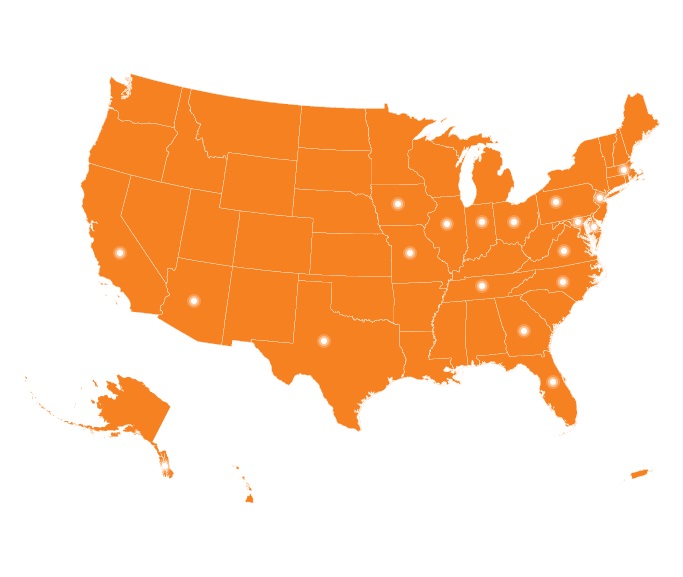

Trusted Across United States

Proudly delivering cutting-edge sealing solutions to leading USA companies.

Why USA Based Manufacturing Companies Choose to Work With Us?

- 50+ years of experience in sealing solutions industry.

- Consistent On-Time Delivery (OTD) rate of 85%, ensuring seamless operations for our clients.

- Delivered sealing solutions to 1,300+ customers across inustries.

- Helped our customers generate a collective revenue of $1.5 billion through reliable and high-quality solutions.

Our USA presence

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Add Your Tooltip Text Here

0

%

indiana

0

%

California

0

%

Massachusetts

0

%

ohio

0

%

maryland

0

%

others

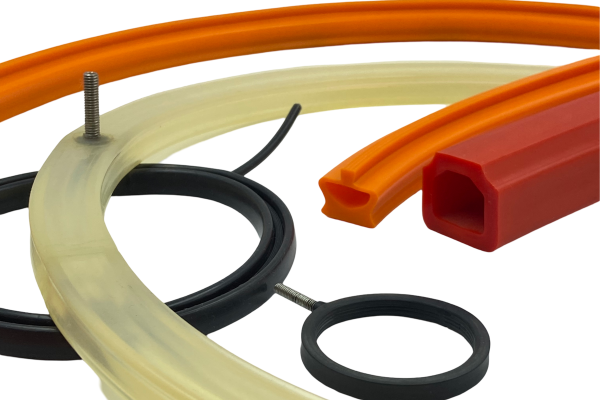

Our Sealing Applications

Robotic Automation System

Gas Tight Door Seal for Hazardous

Pharmaceutical Equipments

Low Smoke Silicone Seals for Trains

Air Tight Clean Room Doors

Inflatable Seals for Butterfly Valves

Types of Rubbers for Inflatable Seals

Material | Temperature Range | Strengths | Limitations |

|---|---|---|---|

EPDM | -50°C to 150°C | Excellent aging, ozone, weather resistance; Flexible at low temperatures | Poor resistance to petroleum oils, acids, and bases |

Neoprene | -40°C to 125°C | Good weather and ozone resistance; Moderate oil resistance; Flame

resistant | Not suitable for strong acids, esters, or gasoline |

NBR | -40°C to 120°C | High resistance to oils and fuels; Good abrasion resistance | Poor resistance to ozone, sunlight, and weathering |

HNBR | -40°C to 165°C | Exceptional oil/fuel resistance; Superior mechanical properties | Higher cost; Limited resistance to strong acids and bases |

Natural Rubber (NR) | -50°C to 80°C | High resilience, flexibility; Good adhesion to metals | Poor resistance to oils, ozone, weathering; Limited

temperature stability |

Silicone (MVQ) | -60°C to 230°C | Excellent temperature resistance; Good weather and UV resistance | Poor resistance to oils, acids; Lower tensile strength |

Fluorosilicone (FVMQ) | -60°C to 200°C | Excellent resistance to oils and solvents; Wide temperature range | Higher cost; Lower mechanical properties than silicone |

FKM (Viton) | -20°C to 200°C | Superior chemical resistance; Excellent high-temp stability | Poor low-temperature performance; Higher cost |

Serving the Unique Needs of USA Industries

Aerospace & Defence Industry

Food & Beverage Industry

Pharmaceutical & Biotechnology

Electronics & Semiconductors

Medical Devices & Healthcare

Energy & Power Industry

Cleanroom & Laboratories

Automotive & Transporation

Construction & Infrastructure

Get a Custom Solution Now

Contact information

Western Polymer Group INC.

3524, Silverside Road, Suite 35B, Wilmington, Delaware 19810-4929.

- sales@westernrubbers.com

Send Us a Message

© 2025 Western Rubbers. All Rights Reserved.