Inflatable vs Reinforced Inflatable Seals; What Engineers Must Know Before Specifying

👀 Real Talk: Not All Seals Are Built the Same

You’re here because you’re designing something that needs to work. Not “just seal” but seal

reliably, cycle after cycle, under pressure, misalignment, or tight validation timelines.

And yet, most failures we see? Come from choosing the wrong inflatable seal type.

“We installed a standard seal. It worked fine… until PQ. Then it bulged. And we scrambled to replace it during audit week.”

That’s a nightmare you don’t need. So let’s break it down.

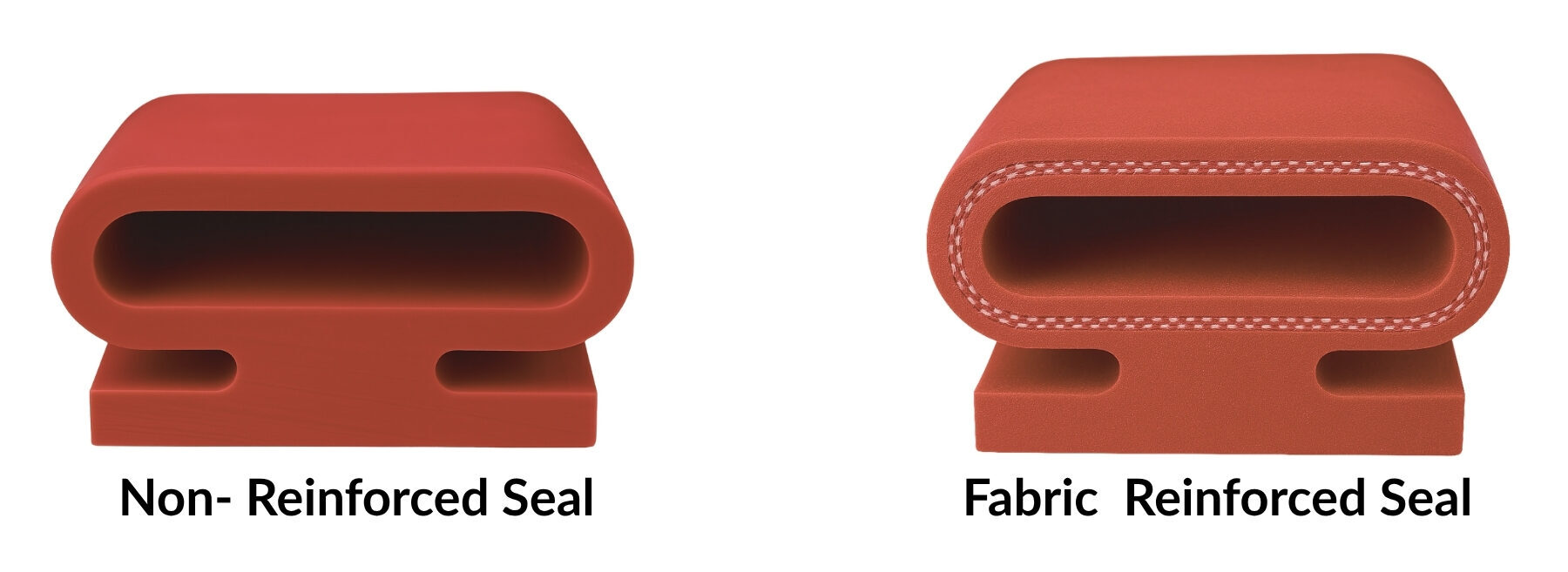

🔍 What’s the Actual Difference

Inflatable seals aren’t all built the same. Choosing between standard and reinforced isn’t just about cost; it’s about reliability under pressure.

Standard inflatable seals are great for static sealing applications like glove ports or occasional closures. They’re made from silicone or EPDM and expand easily, conforming to uneven gaps.

Reinforced inflatable seals, however, include a layer of woven fabric (like Kevlar or Nylon) embedded within the rubber. This reinforcement lets them hold shape, handle high pressure, and repeat cycles with minimal fatigue.

Feature | Reinforced Inflatable Seal | Standard Inflatable Seal |

|---|---|---|

Pressure | Up to 12 bar | ≤ 2 bar |

Material | Silicone , EPDM + Fabric Layer | Silicone, EPDM

|

Use | Repeated cycles, high-pressure or critical systems

| Static/light sealing, low-pressure systems |

Risk if Misused | Holds shape under stress

| May bulge,or leak under stress

|

❗ What Happens When You Guess Wrong?

Here’s what we’ve seen:

A pharma isolator gets validated with a non-reinforced seal. Two weeks later in mid-production, the chamber fails to hold a vacuum. Inspection shows the seal had ballooned under thermal cycling. Result? Downtime, batch rejection, and a furious QA lead.

These are not edge cases. They happen often and quietly ruin budgets.

❌ Engineers Who Chose Wrong Faced:

- Delayed site acceptance tests

- 3X seal replacement costs within a year

- Panic during sterile audit failures

- Derailed production timelines

✅ When Standard Seals Work Just Fine

Standard inflatable seals are not inferior; they just have limits.

When you’re dealing with equipment that operates at low pressure (under 2 bar), has manual access doors, and doesn’t cycle frequently, a standard seal is not only sufficient, it’s ideal. It provides flexibility, fast installation, and better pricing.

But the moment you introduce automation, cleaning agents, or fluctuating pressures, this simplicity becomes a weakness.

🔒 When You Absolutely Need Reinforcement

Reinforced seals are built for control. They’re essential when:

- Pressure regularly exceeds 2.5 bar

- You’re cycling 50+ times a day

- The seal interfaces with robotic arms or trays

- VHP or SIP exposure is expected

Without reinforcement, you risk uneven expansion, long-term deformation, or even rupture, especially in hot, pressurized, or sterilized systems

Why Groove Design Can Make or Break It

Even the best seal will fail if seated in a poor groove.

Grooves that are too tight, shallow, or sharply machined create concentrated stress zones. These stress points pinch the seal during inflation and create premature wear.

Engineers often assume reinforcement compensates for poor groove design but it’s the opposite. Reinforced seals require more thoughtful mounting. You need radiused corners, proper depth, and smooth finishes.

Engineer’s Moment of Truth

Before finalizing that BOM, here’s what to ask:

- Will this seal go through dozens or hundreds of cycles?

- Is there a pressure spike risk, even momentarily?

- Could a failure lead to contamination, lost product, or delayed shipment?

- Will I be the one getting the call if it fails?

If even one of these gives you pause, choose the safe bet and go reinforced.

💬 One Sentence You Don’t Want to Say:

“It was just a seal.”

Because that one seal? It holds pressure. It protects the product. It passes audits. It keeps systems running.

And when it fails, all of that stops.

At Western Rubbers, We Help You:

We Engineer Peace of Mind.

Whether you’re dealing with pressure cycling, robotic arms, or unpredictable gaps, we help you:

- Choose the right inflatable seal for your pressure, fitment, and media

- Optimize groove design for better durability and sealing reliability

- Upgrade to reinforced inflatable seals when your system demands more

- Customize seals to match your equipment geometry and validation specs

🔗 Explore our Inflatable Seal Solutions »

📩 Or speak to our engineers at: sales@westernrubbers.com

Because when your seal fails, everything stops.

Let’s make sure that never happens.

No comment yet, add your voice below!