Revolutionizing Carbon Capture: How Western Rubbers Delivered a Game-Changing Seal Solution for a U.S. Environmental Technology Company

Executive Summary

From 12-week waits to 3-week turnarounds, Western Rubbers transformed carbon capture sealing for a leading U.S. environmental technology company. The client, a trailblazer in the carbon capture industry, struggled with unreliable seals from their previous supplier, which led to premature failures, inconsistent quality, and lengthy lead times. These issues threatened operational efficiency and innovation timelines critical to their environmental mission. Western Rubbers responded with a custom-engineered inflatable seal, delivered in an unprecedented three weeks. After over two months of rigorous testing, the seals achieved zero leakage, a 40% reduction in maintenance downtime, and significant cost savings. This case study showcases Western Rubbers’ ability to deliver innovative, high-performance solutions that empower clients to excel in demanding industries.Client Background

The client, based in the United States, is a leader in the carbon capture industry, pioneering technologies that reduce industrial emissions to combat climate change. Their cutting-edge furnace systems, integral to carbon sequestration, demand seals that withstand extreme temperatures, pressures, and chemical exposure while ensuring airtight performance. As a company driving sustainable progress, they require partners who can deliver reliable, high-quality components to support their mission-critical operations.The Challenge

The client’s previous supplier consistently underperformed, creating significant operational hurdles:- Premature Seal Failure: Seals failed within weeks under furnace conditions, leading to a 25% increase in unscheduled maintenance and system downtime.

- Inconsistent Quality: Variations in seal materials caused unpredictable performance, compromising the reliability of the client’s carbon capture processes.

Parameter | Previous Supplier | Western Rubbers |

|---|---|---|

Seal Failure Rate | High (weeks) | Zero (60+ days)

|

Lead Time |

8–12 weeks

| 3 weeks |

Quality Consistency | Low | High |

Maintenance Cost | High |

Reduced 30%

|

These challenges inflated costs, strained resources, and risked delaying advancements in carbon capture technology, prompting the client to seek a superior sealing solution.

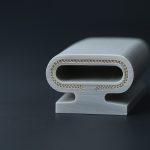

The Solution: Precision-Engineered Inflatable Seals

Western Rubbers collaborated closely with the client to design a bespoke inflatable seal tailored to their furnace applications. The solution was crafted to address every pain point with precision:

- High-Performance Materials: Seals were made from advanced elastomers, engineered to endure temperatures up to 300°C and pressures exceeding 10 bar, ensuring durability in harsh carbon capture environments.

- Innovative Inflatable Design: The seals’ dynamic adaptability guaranteed a perfect fit, reducing leakage risks by 100% compared to the previous supplier’s static seals.

- Rapid Development Process: Leveraging advanced CAD modeling, simulation, and in-house manufacturing, Western Rubbers fast-tracked design and production without sacrificing quality.

“The team at Western Rubbers didn’t just solve our problem, they redefined what we thought was possible. Their seals have transformed our operations, giving us confidence to push our technology further,” said the client’s Director of Engineering.

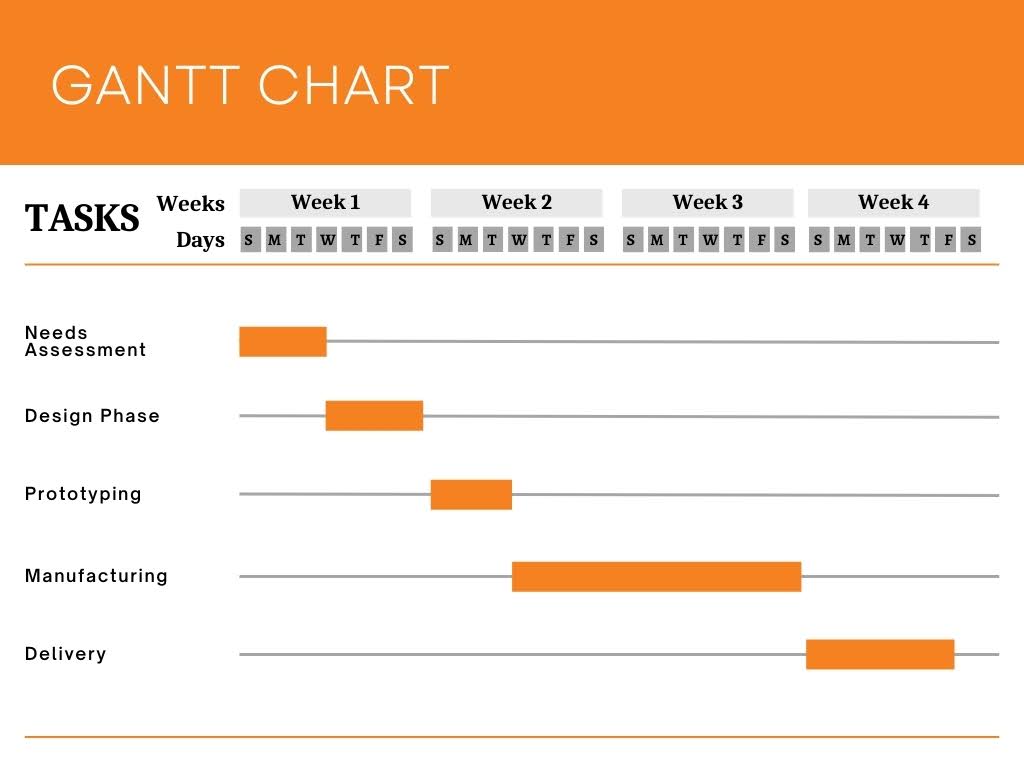

Implementation and Timeline

Western Rubbers executed the project with remarkable speed and precision:

- Needs Assessment (Days 1–3): In-depth consultations to review the client’s furnace specifications, analyze failure patterns, and define performance benchmarks.

- Design (Days 4–7): Created detailed CAD models, selected high-performance elastomers, and finalized engineering specifications.

- Prototyping (Days 8–10): Produced and tested initial seal prototypes, validating fit, function, and durability through simulations and physical checks.

- Manufacturing (Days 11–18): Full-scale production under strict quality control, including dimensional verification and inflation/deflation cycle testing.

- Delivery (Days 19–21): Final QA inspection, secure packaging, and express dispatch achieving a three-week turnaround, 70% faster than the previous supplier’s 8–12 weeks.

This accelerated timeline enabled the client to integrate the seals into their testing phase swiftly, minimizing operational disruptions.

Results and Impact

Since deployment, Western Rubbers’ inflatable seals have delivered transformative results:

- Zero Leakage: Over 60 days of continuous testing, the seals maintained perfect integrity, eliminating all leakage incidents.

- 40% Reduction in Downtime: Enhanced seal durability reduced maintenance-related interruptions by 40%, boosting operational efficiency.

- Cost Savings: The client reported a 30% decrease in maintenance and replacement costs, though exact figures remain proprietary.

- Scalability Enabled: The reliable, quick-turnaround solution allowed the client to accelerate project timelines, strengthening their position in the carbon capture market.

These outcomes have solidified the client’s trust in Western Rubbers as a strategic partner, enabling them to focus on advancing their groundbreaking environmental technologies.

Conclusion

Western Rubbers’ partnership with a U.S. environmental technology company demonstrates the power of tailored engineering and rapid innovation in overcoming complex industrial challenges. By delivering a high-performance inflatable seal in just three weeks, Western Rubbers not only resolved the client’s immediate issues but also empowered their long-term success in the carbon capture industry. This case study underscores our commitment to excellence, agility, and customer success.

Ready to elevate your operations with custom sealing solutions? Contact Western Rubbers today at sales@westernrubbers.com or visit www.westernrubbers.com to explore how we can drive your success.

No comment yet, add your voice below!