Introduction

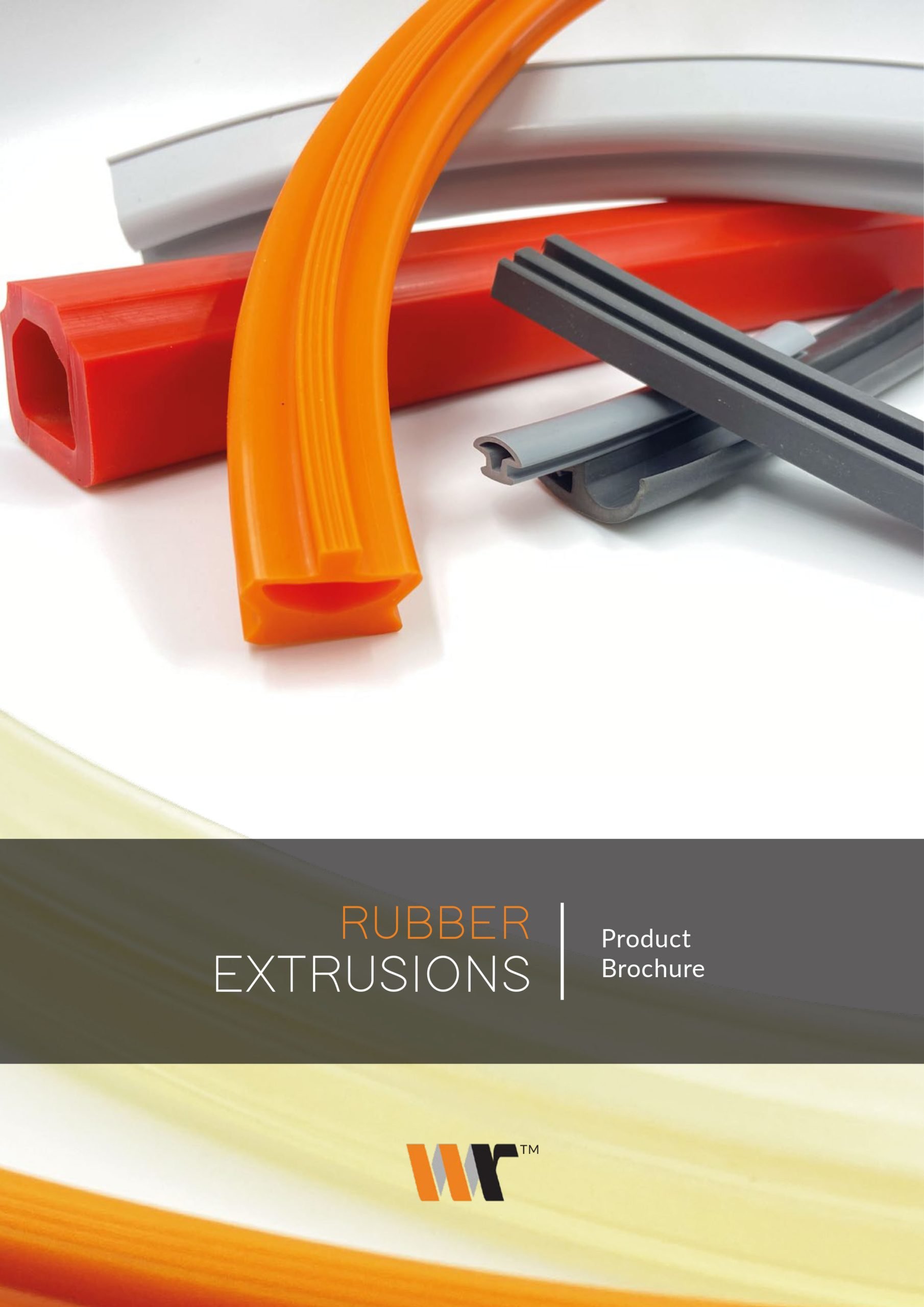

EXTRUSIONS

Western Rubbers specialises in extruding silicone extrusions. Our silicone extrusions are made from compounds that are specially developed using in-house formulations, which make our rubber extrusions not only appealing in aesthetics but also long lasting in extreme environments. We take pride in extruding intricate shapes and designs, which have otherwise been difficult to manufacture. We guide and work with our clients to meet their stringent parameters on compression set, elongation, hardness, density, and other such physical as well as chemical properties which are required in their application.

Introduction

Joined / Vulcanized Extrusion Profiles

A very large number of seals at Western Rubbers are manufactured by splicing and vulcanising elastomer extrusion profiles. The extruded profile is first cut with precision (splicing). The loose ends of this rubber extrusions are then bonded together by applying uncured compound (the same as used in the extruded seal) at the point where the ends meet. This join is then moulded at high temperatures for a specified period of time to form a strong unbreakable bond. Western Rubbers is known for offering the best joins for extruded seals since the joins are compression moulded rather bonded using adhesives.

Features

Products Benefits

HL3 certified compounds

standard dimensions

Types of Rubber Extrusion Profile

U Extrusion SEal

U extrusion seals also known as Rubber U channel or U type rubber

extrusions. One of their primary uses is to provide edge

protection. These kinds of extrusion are predominantly made in EPDM and are primarily used in doors and window hatches.

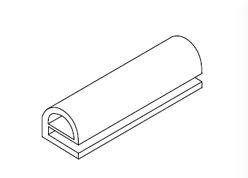

D Extrusion SEal

D extrusion seals have unique design

features that allow them to be hollow from within. This provides a D extrusion seal with excellent rebound properties. This rebound resilience is the reason why D seals tend to last longer in applications like doors, windows, acoustics and impact absorption.

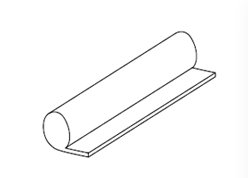

P Extrusion SEal

The stem in P seals enables its attachment to a retainer which makes P seal rubber extrusions very versatile. They are also referred to as musical notes seals and tadpole seals. P seals are manufactured in elastomers such as silicone, EPDM and TPE.

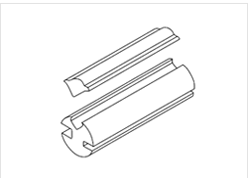

H Extrusion SEal

H extrusion seals are used between windows and doors for shock absorption and heat and sound insulation. When used in glass facades, these extrusions are also known as glazing rubber gaskets. They are primarily manufactured in EPDM and silicone and tend to have excellent weather resistance.

E Extrusion SEal

E type extrusion seals are also known as refrigerator seals. These seals have an added benefit of hollow bulbs. Hollow bulbs provide maximum compressibility and rebound resilience resulting in excellent sealing. These E seals rubber extrusions can be modified to have ridges on the sealing surface for added grip.

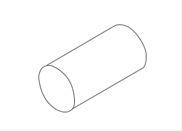

Rubber cords

Solid seals or rubber cords are primarily manufactured in silicone, EPDM, BUNA N and FKM. These rubber cords can be circular, rectangular, trapezoidal or triangular depending on the application. Solid rubber cords

extrusions are used in

autoclaving systems, boilers, mechanical fixtures, chemical drums, filtration systems, manhole covers and many such applications.

our use cases

Applications

Rubber extrusions are used for securely sealing doors (door seals), windows (window seals), lids,

and any other such opening in a number of industries like: