How a US Pharmaceutical Leader Turned Leaks into Legends with Fabric-Reinforced Seals

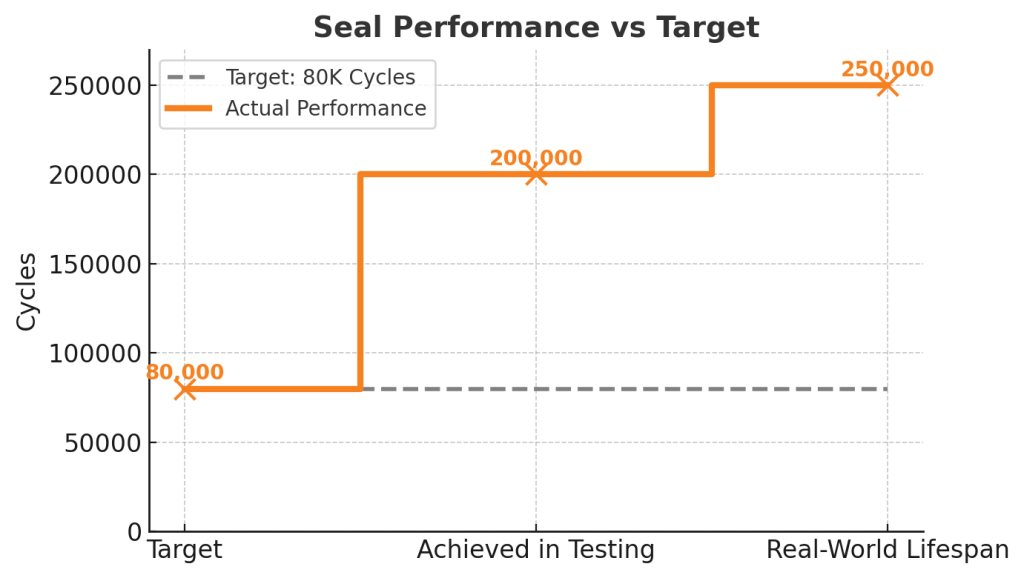

A leading US-based company in the Pharmaceutical industry battled persistent failures with non-fabric reinforced seals that couldn’t meet their rigorous standards. These seals fell short of the 80,000-cycle testing target and the 250,000-cycle life expectancy required for their hydraulic systems. Western Rubbers stepped in with custom fabric-reinforced seals that crushed 200,000 leak-free cycles in testing 2.5 times the goal and guaranteed the 250,000-cycle lifespan. The result? Zero failures, unmatched reliability, and a reputation restored to its full glory.

The Challenge: A Leaky Nightmare

This US company giant powered some of the toughest equipment in the industry, from bulldozers to excavators. But a hidden flaw was dragging them down: non-fabric reinforced seals that couldn’t handle the intense pressure of hydraulic systems. Leaks were a constant headache, stalling projects and frustrating clients who expected rock-solid performance. The company set clear targets to fix the issue:

- Testing Target: Seals must endure 80,000 cycles in lab tests without a single leak.

- Lifespan Goal: Seals needed to last at least 250,000 cycles in real-world conditions.

Their existing seals were failing well before the testing mark, turning reliability into a growing concern. They needed a solution that didn’t just stop the leaks but set a new standard for durability.

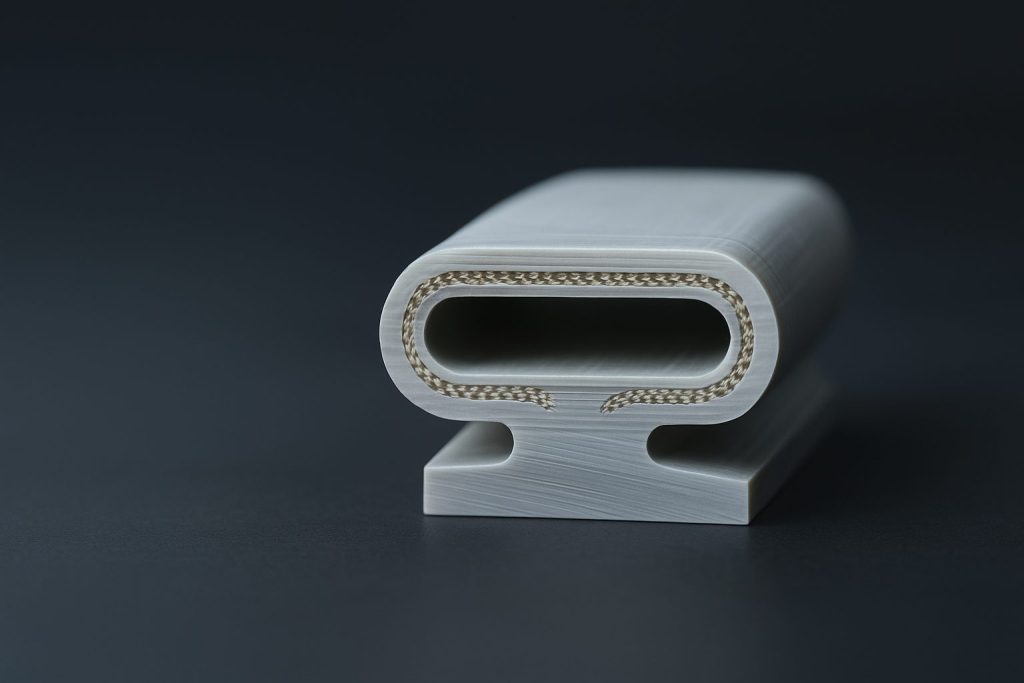

The Solution: Weaving Strength into Every Seal

Western Rubbers saw the challenge as a chance to shine. After analyzing the failing seals, we zeroed in on the problem: non-fabric materials that buckled under repetitive stress. Our fix? Fabric-reinforced seals, engineered with advanced composites built to thrive under pressure.

This wasn’t a generic patch. We partnered closely with the company’s team, diving deep into their hydraulic systems to craft seals tailored to their exact needs. “Western Rubbers felt like an extension of our crew,” said a company spokesperson. We promised seals that would hit the 250,000-cycle mark and prove it in the toughest conditions. To back it up, we put the seals through a brutal testing gauntlet, simulating the harshest environments their machines would face.

The Results: From Breakdowns to Breakthroughs

The fabric-reinforced seals didn’t just deliver they rewrote the rules:

- Unstoppable Durability: Breezed through 200,000 cycles in testing 2.5 times the 80,000-cycle requirement with zero leaks or wear.

- Lasting Power: Confirmed to exceed the 250,000-cycle lifespan in real-world use.

The impact was a game-changer for the company:

- Leak-Free Operations: Seal failures disappeared, keeping equipment running and projects on track.

- Reputation Recharged: Clients went from frustrated too impressed, solidifying the company’s leadership in the construction machinery industry.

“These seals turned our biggest weakness into our greatest strength,” said a company representative. “Our equipment is now a benchmark for reliability, and our customers are thrilled.”

Why It Matters

This story is about more than plugging leaks; it’s about transforming a liability into a competitive edge. Western Rubbers’ fabric-reinforced seals gave this US company the confidence to push their machines to the limit, knowing they’d hold strong. By smashing the 80,000-cycle test with 200,000 leak-free cycles and securing a 250,000-cycle lifespan, we helped them reclaim their place at the top. It’s a testament to what happens when innovation meets collaboration.

Conclusion

By swapping failing non-fabric seals for custom fabric-reinforced ones, Western Rubbers empowered a US leader to surpass their 80,000-cycle testing goal with 200,000 leak-free cycles and achieve a 250,000-cycle lifespan. Failures are gone, reliability is rock-solid, and their reputation is stronger than ever. This partnership proves that the right solution can turn setbacks into victories. Got a tough challenge? Let’s craft your next win together.

No comment yet, add your voice below!