Our Products

Precision Silicone Extrusions

for Demanding Applications

Durable and flexible silicone extrusions crafted for superior performance.

Introduction

Why Manufacturing Companies Choose Our Silicone Extrusions

Western Rubbers offers high-quality custom silicone extrusions designed to handle rigorous industrial environments. Our silicone extrusion profiles deliver unmatched flexibility, durability, and compliance with medical and food safety standards. Whether you need silicone extrusion solutions for demanding applications, we ensure precision and reliability in every product.

Subcategories

Explore Our Silicone Extrusions

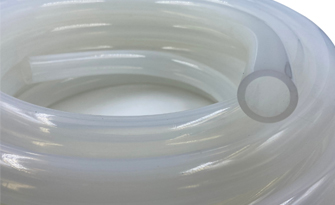

Silicone Tubing

Flexible and resilient tubing for fluid handling and insulation.

silicone cords

Reliable silicone cords designed for sealing and gasketing.

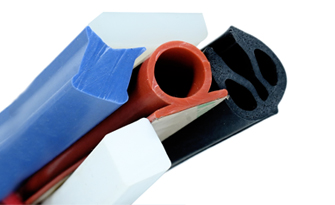

silicone Profile

Custom shapes tailored for industrial sealing and insulation.

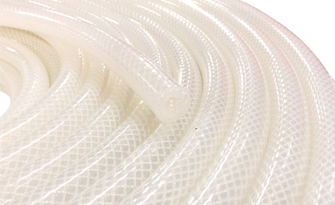

silicone Hoses

Silicone Strips

Versatile strips for sealing, spacing, and cushioning.

silicone Rubber sheets

Durable sheets for sealing, protection, and insulation.

silicone sponge extrusions

Lightweight sponge extrusions for shock absorption and sealing.

Silicone Joined & Vulcanized Parts

Flexible and resilient tubing for fluid handling and insulation.

key features and benefits

Key features of our silicone extrusions

Durability

Flexibilty

Compliance

Scalability

Our Service Areas

Industries We Serve

Medical & Healthcare

Food & Beverage

Pharmaceuticals

Chemical-resistant solutions for production facilities.

Automotive

Industrial Manufacturing

Catalog Download

Download Our Silicone

Extrusions Catalog

Questions and Answers

Frequently Asked Questions

We offer a range of materials including Natural Rubber, silicone, EPDM, Nitrile (NBR), Viton (FKM), Fluorosilicone(FVMQ), Styrene-Butadiene Rubber(SBR), Thermoplastic Elastomer(TPE), and Neoprene. Each material is selected based on its application suitability.

We maintain industry-standard tolerances as per RMA (Rubber Manufacturers Association) guidelines and can achieve tight tolerances for precision applications.

We can extrude profiles with widths ranging from 25 meters to over 100 meters, depending on the material and complexity of the design.

Yes, we provide FDA-compliant materials. Our materials are US FDA 21 CFR approved.

Yes, we offer extrusions with pressure-sensitive adhesive backing, as well as special coatings for UV resistance, anti-static properties, and enhanced durability.

Lead times vary based on complexity and quantity but typically range from 3 to 4 weeks for custom orders.

Yes, we offer precision cutting, splicing, hole punching, and corner bonding services as per customer requirements

Our MOQ depends on the material and profile complexity, but we strive to accommodate both small and large orders.

We have stringent quality control processes, including material testing, dimensional checks, and performance evaluations to ensure defect-free products.

Yes, we provide UV-resistant, weatherproof rubber extrusions, particularly in EPDM and silicone, for outdoor and harsh environment applications.

Yes, our rubber extrusions are designed for sealing in high-pressure and vacuum applications.

We can recommend the best material and design for your specific needs.

inquiry form

Need Custom Silicone Extrusions?

Contact Us

Let our experts guide you in selecting the right extrusion for your needs.