Top 6 Industries You Didn’t Know Run on Inflatable Seals And Why Skipping Them Could Be a Costly Mistake

In precision engineering, the smallest leak isn’t just an inconvenience it can derail production, compromise safety, and cost millions. Inflatable seals, though often hidden from sight, are the invisible backbone of reliability in high-stakes environments. They expand and contract on demand, creating airtight barriers where traditional gaskets fail.

Today, they’re not just useful, they’re indispensable. Six global industries now rely heavily on inflatable sealing technology for performance, compliance, and competitive advantage. If you’re not designing with them in mind, you’re already a step behind.

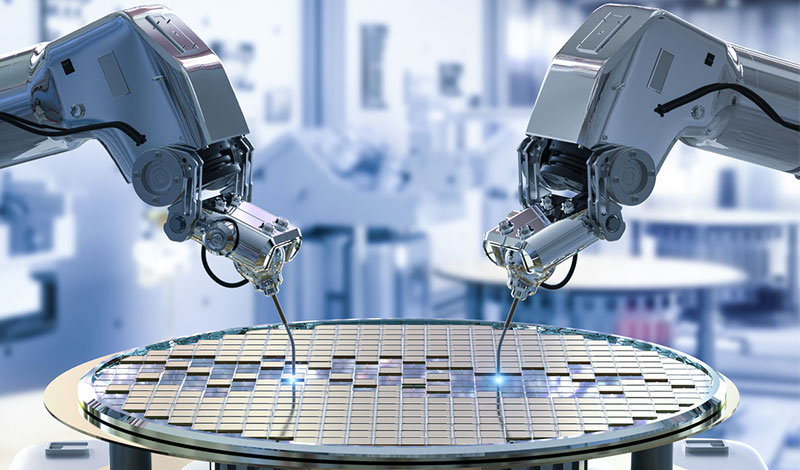

Semiconductor Industry

Semiconductor manufacturing is built on precision; even a microscopic particle can destroy an entire wafer batch. Inflatable seals are critical in wafer fabrication tools, vacuum chamber doors, load locks, and transfer modules, where ultra-clean, particle-free environments are mandatory. They conform perfectly to irregular surfaces, maintaining airtight integrity under vacuum conditions.

Most equipment in this space adheres to ISO 14644 cleanroom classifications, so seals must be made from low-outgassing, contamination-resistant elastomers like FKM or high-purity silicone. Fabric-reinforced seals are often preferred here for their ability to handle repeated vacuum cycles, extreme temperature ranges (−60 °C to +200 °C), and higher differential pressures. In lower-stress systems or wafer transport enclosures, non-reinforced options can still deliver excellent sealing with more flexibility.

In short, inflatable seals protect yield, extend tool uptime, and directly impact fab profitability. They’re not an accessory, they’re an essential.

Pharmaceutical Industry

In pharma, every seal is part of your compliance strategy. Inflatable seals are used in autoclaves, isolators, cleanroom doors, fluid bed dryers, and sterile transfer ports, where they provide reliable, contamination-free sealing in environments governed by GMP, FDA 21 CFR 177.2600, and USP Class VI standards. Their ability to inflate only when needed reduces wear and energy use while maintaining validated sterile barriers.

Material choice is critical. Platinum-cured silicone is often the go-to for cleanroom and bioprocessing lines due to its biocompatibility and resistance to sterilizing agents like steam and hydrogen peroxide. For isolators and high-pressure autoclaves, fabric-reinforced seals provide dimensional stability and extended cycle life. In glove-box doors and modular cleanrooms, non-reinforced designs offer faster actuation and easier installation.

Beyond compliance, these seals can cut validation time by up to 30% and improve cleaning efficiency, a tangible advantage when product safety and regulatory readiness are non-negotiable.

Vacuum Impregnation Industry

Vacuum environments demand repeatable, leak-free performance and inflatable seals are engineered for precisely that. They’re deployed in vacuum dryers, dispensing lines, and bubble-tight enclosures where they ensure consistent sealing even under fluctuating pressures. They’re also widely used in vacuum impregnation systems for metal and electronics, where they enable perfect chamber sealing to evacuate air and allow precise sealant penetration.

For most static and dynamic vacuum applications, reinforced seals are recommended for their pressure resistance and dimensional stability. If flexibility or rapid cycling is more important for example, in smaller dispensing valves or frequent open-close doors non-reinforced silicone or EPDM can be ideal.

Their adaptability to custom geometries also reduces assembly complexity and cost, while their reliability ensures stable performance in processes where even a minor leak can compromise product quality.

Oil and Gas Industry

Oil and gas operations push materials and systems to their limits. Inflatable seals are used in pipeline isolation tools, pressure vessels, blow-out preventers, and access hatch environments that often see pressures exceeding 10,000 PSI and exposure to corrosive chemicals. Their ability to expand rapidly for emergency isolation enhances worker safety, minimizes environmental risk, and reduces downtime during maintenance.

Material selection is crucial here. FKM and HNBR are commonly used for their resistance to hydrocarbons and aggressive media. Fabric-reinforced designs are strongly recommended in this sector because of their strength, durability, and ability to maintain sealing integrity under large diameters and extreme pressure differentials.

In an industry increasingly driven by ESG goals and zero-incident targets, inflatable seals are not just sealing components, they’re a safety system, a compliance tool, and a cost-saver all in one.

Food Processing Industry

Food and beverage plants operate under some of the strictest hygiene standards in manufacturing. Inflatable seals are found in autoclaves, pressure vessels, mixing tanks, and transfer hatches, where they enable fast, sanitary sealing while meeting FDA, USDA, and EU 1935/2004 food-contact regulations. Their smooth surfaces and non-porous materials make cleaning simple and reduce bacterial risks.

Non-reinforced platinum-cured silicone is typically used here for its flexibility, fast inflation, and compliance with hygienic requirements. Where repeated thermal cycling or larger gaps are present, fabric-reinforced options can extend service life and reduce the risk of deformation.

They don’t just meet hygiene standards, they also shorten cleaning cycles, cut downtime, and improve throughput, which directly improves plant productivity and ROI.

Aerospace Industry

In aerospace, weight, performance, and reliability are everything. Inflatable seals are used in aircraft cabin doors, access panels, avionics compartments, satellite payload bays, and ground-support systems. They ensure pressure integrity, allow quick access for maintenance, and function reliably under vibration, extreme temperature, and altitude fluctuations.

Most aerospace applications require compliance with AS9100 and stringent flammability standards. Fabric-reinforced FVMQ or FKM seals are commonly used here due to their superior resistance to ozone, fuel, and temperature extremes. Non-reinforced options are occasionally used in ground-support systems where flexibility and quick replacement outweigh extreme performance needs.

By replacing heavier metal seals, inflatable options can reduce weight by up to 20%, improve fuel efficiency, and extend maintenance intervals crucial benefits in an industry where every kilogram and every cycle counts.

The Smallest Component With the Biggest Impact

Inflatable seals might not get the spotlight, but they quietly shape performance, safety, and compliance across industries. They protect semiconductor yields, keep pharmaceutical products sterile, enable vacuum precision, improve oil and gas safety, streamline food production, and support aerospace reliability.

Choosing the right design reinforced or non-reinforced, fabric or standard isn’t just a detail. It’s a decision that affects uptime, validation time, regulatory success, and long-term cost.

Ready to See the Difference

Start by evaluating just one critical sealing point in your system. Ask whether an inflatable seal could make it safer, more efficient, more compliant, or more cost-effective. Chances are, it will.

If you’re ready to see how tailored sealing solutions can transform your equipment’s performance, talk to our team. We’ll help you choose the right material, design, and configuration backed by real-world data, certifications, and application expertise.

No comment yet, add your voice below!