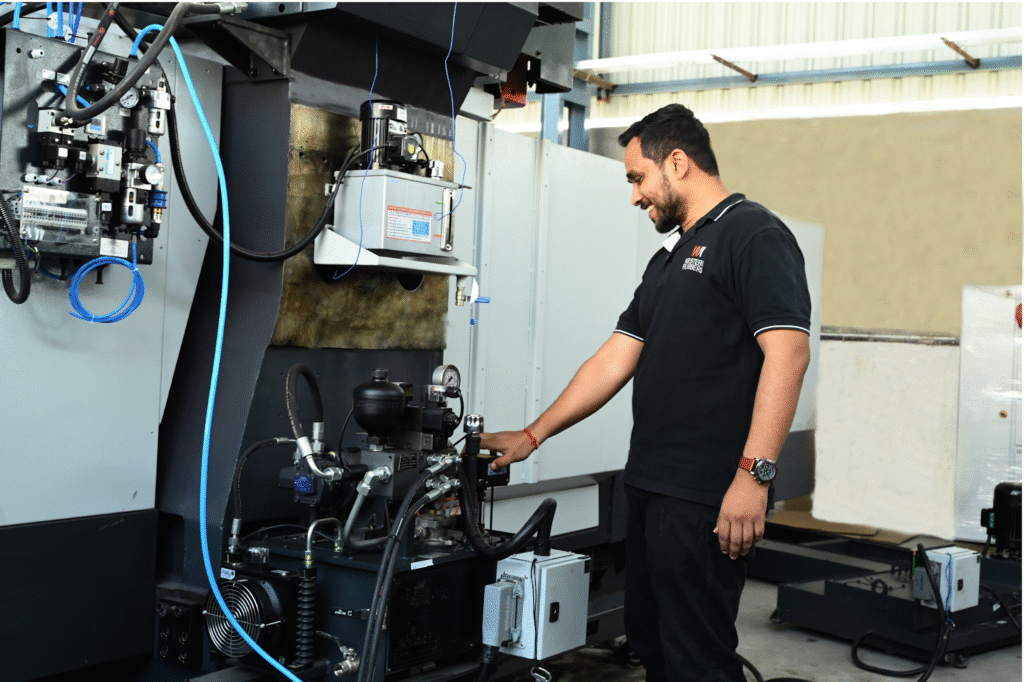

Western Rubbers Elevates Tooling Precision with New VMC Machine Installation

What exactly is a VMC Machine?

A Vertical Machining Center (VMC) is a computer-controlled milling machine that operates on a vertical spindle axis. Widely used in the mold and tooling industry, it enables the production of complex, high-accuracy components by precisely machining cavities, slots, and surfaces on various mold materials. For us, this means faster turnaround and higher-quality tooling for your rubber products.

Specs That Matter: What Our VMC Can Do

Our newly installed VMC enhances our tool room with:

- High spindle speeds for faster material removal

- Multi-axis control for creating intricate mold geometries

- Consistent accuracy and repeatability

- Compatibility with mold-grade materials such as tool steel, aluminum, and stainless steel.

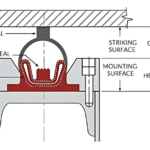

This investment allows us to manufacture rubber molds that are precise, repeatable, and

application-specific — whether it’s for inflatable seals, diaphragms, or custom extrusions.

Why This Matters to Our Clients

What Our Team Says

“With the VMC, we now create highly complex molds with greater control and much

faster turnaround. This significantly improves our R&D and NPD capabilities.”

—(person name), Tooling Head, Western Rubbers

What’s Next?

Need custom rubber parts with tight tolerances and shorter lead times?

📩 Get in touch or email us at sales@westernrubbers.com to discuss your mold

development needs.

[Suggested Internal Links]:

Want to know more about who we are and what drives our innovation?

👉 About Western Rubbers

No comment yet, add your voice below!