Why Inflatable Seals Fail Prematurely:The Data Behind the Downtime

Inflatable seals rarely fail overnight. They fail slowly, quietly, and for reasons that engineers often overlook until the leak test fails, the pressure drops, or production grinds to a halt.

We collected real-world failure data across isolators, valves, hatches, and industrial equipment. What emerged was a clear pattern: six root causes account for nearly all premature inflatable seal failures and each one has its own data fingerprint.

Here’s the story the numbers tell.

1. Overpressure: The Failure That Hits Fast and Hard

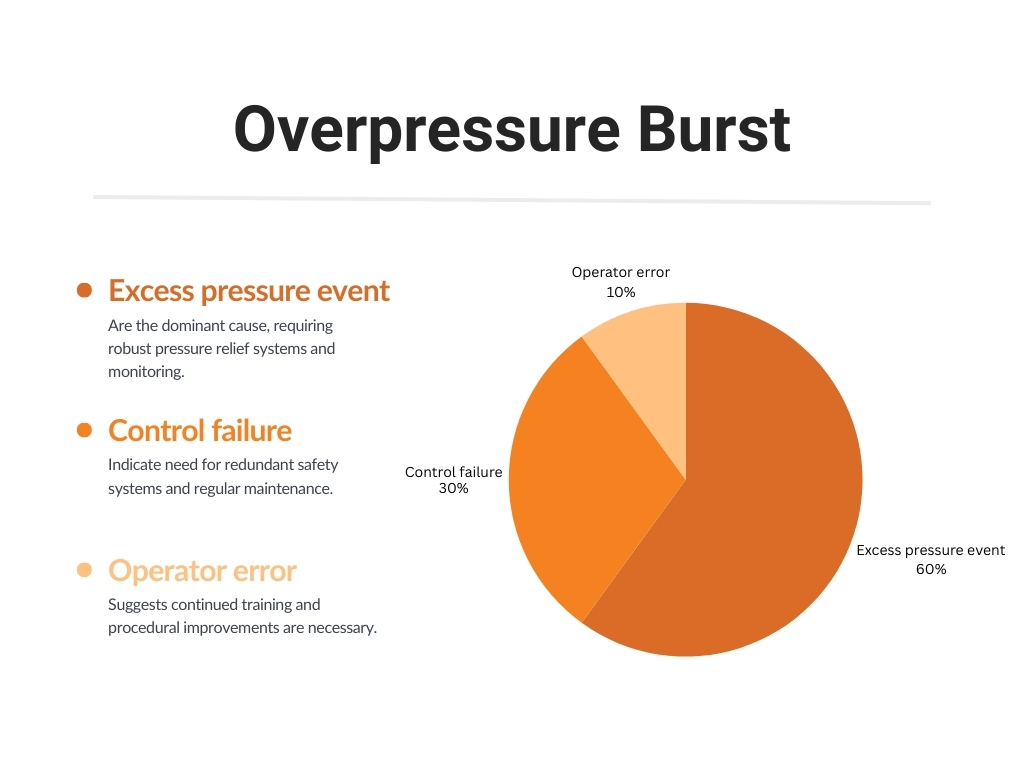

If inflatable seals had a single nemesis, it would be overpressure. Our data shows that 60% of burst failures happen simply because the seal was inflated beyond what it was designed to handle. Another 30% come from control system failures drifting regulators, faulty valves, or pressure spikes no one noticed.

Only 10% stem from direct operator error, but that tiny percentage has caused some of the most expensive shutdowns. In one case, a 25% overpressure event caused a rupture and a 10-hour shutdown worth $75,000.

Overpressure isn’t dramatic, it’s predictable. And preventable.

2. Material Mismatch: When Chemistry and Elastomers Don’t Get Along

Material selection quietly determines the fate of the seal. Over half of all material-related failures (50%) occur because the elastomer wasn’t compatible with the chemical environment. Another 35% stem from heat degradation, especially in systems with aggressive sterilization, while 15% come from repeated VHP/autoclave exposure.

Silicone, EPDM, FKM, PTFE each material is brilliant in the right context and disastrous in the wrong one.

A mismatched material won’t fail on day one; it will slowly lose elasticity, swell, or harden, setting the stage for leaks months later.

Material mismatch is the seal failure equivalent of “wrong person, wrong environment.”

3. Cyclic Fatigue: The Slow Burn That Engineers Forget to Count

Not all seals operate dynamically but the ones that do face constant inflation-deflation cycles. The data is merciless here: 70% of fatigue-related failures come from cycle counts exceeding the seal’s design life. Another 20% arise from reinforcement structures breaking down, and 10% from rapid, aggressive cycling.

One refinery extended seal life from six months to 20,000 cycles simply by switching to reinforced seals.

Fatigue isn’t visible early on, that’s why it’s dangerous.

4. Installation & Groove Mistakes: The Most Avoidable Failures in the Industry

Ask any seal manufacturer: half their troubleshooting calls lead back to installation errors. Our data backs this up. 50% of these failures come from misalignment, 30% from rough grooves, and 20% from stretching the seal during installation.

These aren’t manufacturing defects.

They’re human ones.

A perfectly engineered seal installed in a poorly machined groove will fail every time. A turbine OEM once lost 20% system efficiency purely due to groove errors.

Installation is not a step. It’s a skill.

5. Poor Maintenance: The Most Common But Least Glamorous Reason

Maintenance doesn’t fail seals lack of maintenance does.

And the numbers tell the whole story:

- 60% of maintenance-related failures happen because inspections were skipped

- 25% because debris or lint contaminated the groove

- 15% because cleaning was incomplete or rushed

Inflatable seals don’t demand much.

Just timely checks, IPA wipe-downs, and a clean groove.

But skipping these?

That’s how micro-tears turn into full leaks.

6. Surface & Design Flaws: Small Imperfections, Big Problems

You can choose the right material, the right pressure, and the right installation… and a single machining mark can undo all of it.

Surface-related failures broke down into:

- 55% machining marks

- 30% tolerance errors

- 15% poor design geometry

The tiny details inside a groove, the radius, the microfinish, the uniformity determine whether a seal inflates evenly or fails validation.

This is why specifications like Ra < 32 µin and proper radiusing aren’t “nice-to-haves.” They’re non-negotiables.

Seals Don’t Fail Randomly They Fail Patternedly

Look at the data long enough, and the pattern becomes unmistakable:

Most failures are predictable.

And most predictable failures are preventable.

By addressing these six causes with the percentages as your guide engineers can extend seal life dramatically while reducing downtime, costs, and validation headaches.

Inflatable seals are simple.

Their failures aren’t.

No comment yet, add your voice below!