Executive Summary

A confidential semiconductor OEM was struggling to get a new advanced packaging tool through prototype validation. Every leak test failed. The culprit? Micro-gaps at the end-plug interface the design relied on groove fitment alone with no seal.

With the hardware geometry frozen and cleanroom standards to meet, redesigning the assembly would have delayed the NPD program by months. The OEM needed a drop-in sealing solution that would work immediately, without compromising cleanliness or performance.

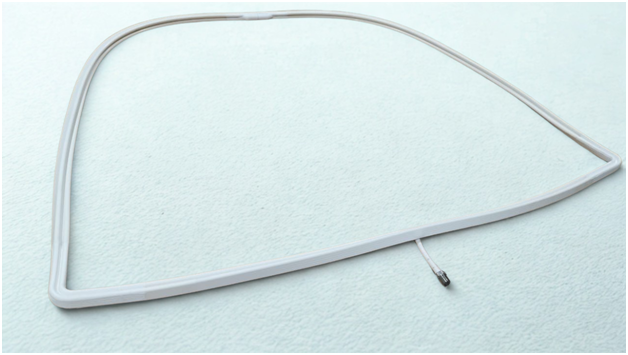

Western Rubbers delivered a custom groove-matched elastomer seal that eliminated leak paths, met cleanroom requirements, and installed without hardware changes. In just ≈8 weeks, the prototype went from failing every test to achieving zero leakage and first-pass validation keeping the launch schedule intact.

Client Snapshot

Confidential OEM manufacturing advanced packaging systems for semiconductor production, where even microscopic leaks can compromise wafer yield, process stability, and equipment reliability.

The Problem

- The prototype’s end plugs depended solely on groove fitment, creating micro-gaps under vacuum that caused leaks in 100% of validation tests.

- Groove dimensions and assembly design were fixed, eliminating the option for re-machining or major geometry changes.

- The seal had to meet stringent cleanroom compliance, low outgassing, zero particulates, and chemical compatibility.

- Any leak, however small, would have failed acceptance criteria, delaying product launch and customer delivery commitments.

Our Approach

- Pinpointed the leak path by reviewing groove geometry, tolerance stack-ups, and surface finish with the client’s engineers.

- Engineered a groove-matched seal profile that created uniform compression across the full length, removing dead zones at the ends.

- Specified a semiconductor-grade elastomer for cleanroom compatibility, long-term stability, and low outgassing.

- Prototyped and tested in just two design loops, using vacuum decay testing to confirm performance.

- Delivered a retrofit-ready seal that dropped into the existing hardware, avoiding 4–6 weeks of potential redesign and revalidation.

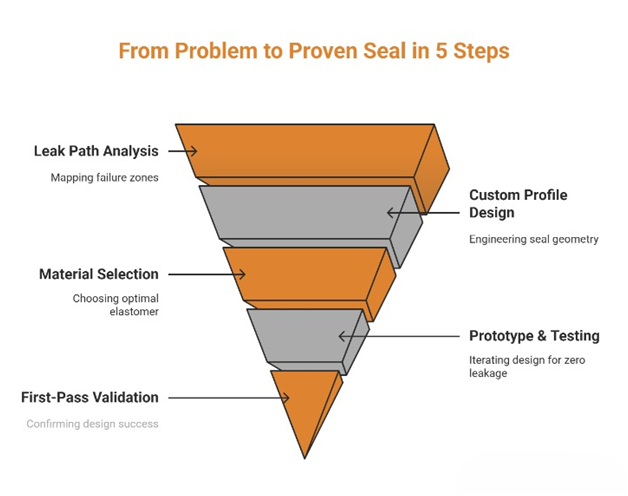

From Problem to Proven Seal in 5 Steps

A streamlined process that moved the project from repeated failures to first-pass validation in just 8 weeks.

- Leak Path Analysis – Identified failure zones at the plug–groove interface.

- Custom Profile Design – Developed groove-matched geometry for uniform compression.

- Material Selection – Choose cleanroom-grade, low-outgassing elastomer.

- Prototype & Testing – Built and tested prototypes, iterating to zero leakage.

- First-Pass Validation – Passed all tests without hardware changes.

Solution Highlights

- Geometry: Groove-matched elastomer profile for continuous, edge-to-edge sealing at end plugs.

- Material: Cleanroom-compliant elastomer with low outgassing and stable sealing recovery.

- Integration: Drop-in installation, saving an estimated 4–6 weeks by avoiding redesign work.

Validation & Testing

- Method: Vacuum decay testing at operational pressures.

- Process: Multi-cycle testing over two weeks to confirm repeatable sealing performance.

- Pass Criteria: Zero measurable leakage within test sensitivity limits achieved in every cycle.

Results

Metric | Before | After | Benefit |

|---|---|---|---|

Leak Rate | Failed every validation test | Zero leakage in all tests | 100% leak elimination secured compliance |

Validation Approval | Multiple failed attempts | First-pass approval | Protected NPD schedule |

Hardware Changes | Redesign likely required | No redesign needed | Avoided 4–6 weeks of rework |

Time to Validation | Delayed | 8 weeks from design start | Weeks saved, faster time-to-market |

Client Feedback

“The custom seal integrated seamlessly and eliminated the leak immediately without changing our hardware. We moved forward to production with full confidence.”

— Lead Mechanical Engineer

No comment yet, add your voice below!