Why Inflatable Seals Fail Prematurely – And How Engineers Can Prevent It

Inflatable seals are critical for OEMs designing leak-proof systems in demanding industries like chemical processing, oil and gas, and aerospace. However, inflatable seal failure can lead to costly downtime, safety risks, and unplanned maintenance. From seal burst to material degradation, understanding the causes of failure and how to prevent them is essential for engineers. In this blog, Western Rubbers, a leading inflatable seals manufacturer, explores why inflatable seals fail and offers actionable strategies to ensure reliability, backed by real-world data and insights.

Common Causes of Inflatable Seal Failure

1. Overpressure and Seal Burst

Overpressure is a leading cause of inflatable seal failure, where seals are inflated beyond their design limits, resulting in seal burst. This is common in high-pressure systems like industrial valves or aerospace hatches when inflation controls are imprecise.

- Why It Happens: Pressure spikes or incorrect settings exceed the seal’s tensile strength (typically 100-200 psi for standard seals).

- Example: A chemical plant valve seal burst due to a 25% overpressure event, causing a 10-hour shutdown costing $75,000.

2. Material Mismatch

Using materials not suited for the environment accelerates inflatable seal failure. For instance, standard rubber degrades in high-heat or corrosive settings, unlike silicone inflatable seals, which resist temperatures up to 500°F and harsh chemicals.

- Why It Happens: Engineers may overlook factors like chemical exposure or thermal cycling.

- Example: A pharmaceutical facility faced seal degradation in a sterilizer due to non-FDA-compliant materials.

3. Improper Installation and Design

Misaligned surfaces or inadequately molded rubber reinforcements can cause uneven stress, leading to premature failure of inflatable seals.

- Why It Happens: Lack of collaboration with an inflatable seals manufacturer during design.

- Example: A misaligned inflatable gasket in a gas turbine reduced sealing efficiency by 20%.

4. Wear from Cyclic Loading

Repeated inflation-deflation cycles in dynamic applications, like valve actuators, can fatigue inflatable seals, causing cracks or loss of elasticity.

- Why It Happens: Seals without reinforced inflatable seal designs may fail after 5,000-10,000 cycles.

- Example: An oil refinery replaced seals every six months due to cyclic fatigue in control valves.

5. Inadequate Maintenance

Neglecting inspections can allow micro-tears or material wear to escalate into a seal burst or leakage.

- Why It Happens: No routine monitoring of inflation pressure or seal condition.

- Example: An aerospace OEM incurred a $100,000 repair after missing early wear signs in a hatch seal.

Mini-Case Study: Preventing Seal Burst in a Petrochemical Valve

A petrochemical OEM faced recurring seal bursts in a high-pressure ball valve, leading to leaks and 15 hours of monthly downtime. By partnering with Western Rubbers, they implemented reinforced inflatable seals made from silicone. After FEA-guided design and pressure testing, the new seals withstood 20,000 cycles, reduced downtime by 80%, and saved $120,000 annually. This highlights the importance of material selection and collaboration with an experienced inflatable seals manufacturer.

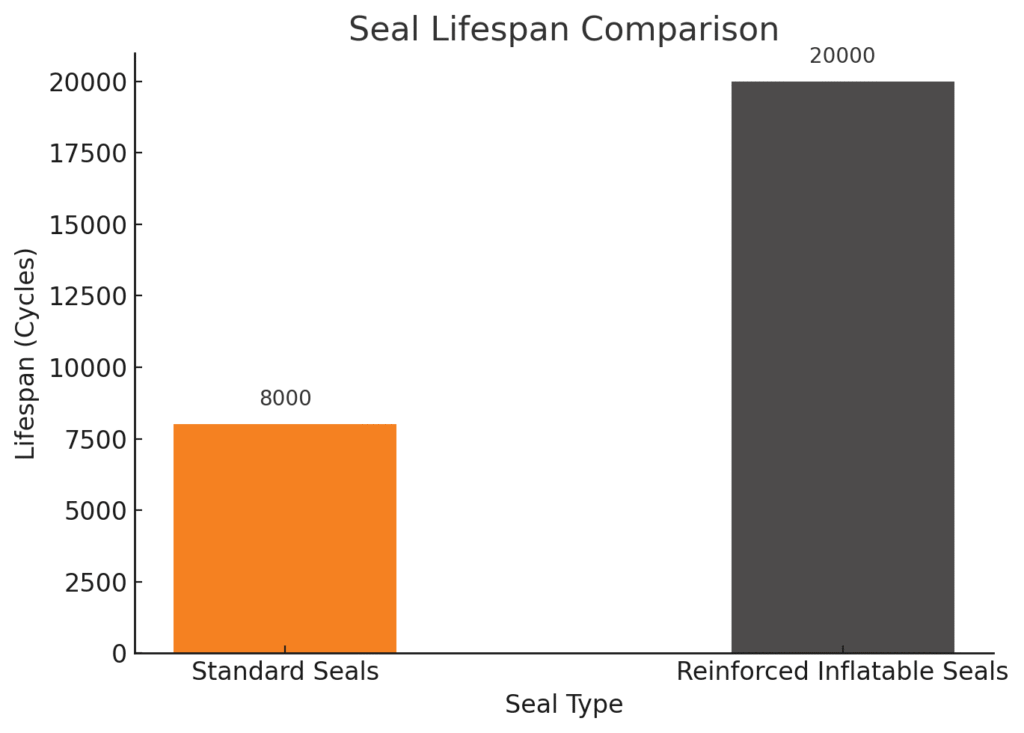

Visualizing Seal Failure Rates

The chart below compares the lifespan of standard vs. reinforced inflatable seals under cyclic loading, based on industry testing data.

This chart illustrates how reinforced inflatable seals significantly outperform standard seals, reducing the risk of inflatable seal failure in dynamic applications.

How Engineers Can Prevent Inflatable Seal Failure

1. Choose the Right Material

Select silicone inflatable seals or reinforced inflatable seal designs for harsh environments. Silicone inflatable seals offer chemical resistance and thermal stability, ideal for oil and gas or pharmaceutical applications. Western Rubbers provides FDA- and API-compliant options.

- Actionable Tip: Request material testing data from your inflatable seals manufacturer. Explore our silicone inflatable seals https://www.westernrubbers.com/inflatable-seals/.

2. Optimize Inflation Systems

Prevent seal bursts with precise pressure regulators and sensors, keeping inflation within 5-20 psi for most inflatable seals.

3. Use Reinforced Designs

Incorporate molded rubber reinforcements in reinforced inflatable seals to handle cyclic stress. Fabric layers or custom profiles enhance durability.

4. Ensure Proper Installation

Collaborate with your inflatable seals manufacturer for installation guidelines to avoid misalignment and uneven inflation.

- Actionable Tip: Request on-site training from Western Rubbers

https://www.westernrubbers.com/contact-us/.

5. Implement Proactive Maintenance

Regular inspections and pressure monitoring can detect micro-tears or wear before they cause inflatable seal failure.

Why Choose Western Rubbers?

As a leading inflatable seals manufacturer, Western Rubbers delivers custom inflatable seals and inflatable gaskets to prevent seal bursts and ensure reliability. Our services include:

- Prototyping and Testing: FEA and pressure testing for custom designs.

- Certified Materials: FDA, API, and AS9100-compliant silicone inflatable seals.

- Failure Analysis: Free analysis to diagnose inflatable seal failure .

Why Wait for the Next Seal Failure?

You don’t need another shutdown or failed test to take action.

Our custom-engineered inflatable seals solve the problem at the root: no more guesswork, no more rework.

Send us your drawing. In 48 hours, we’ll tell you exactly what your system needs.

Design it right once, and never think about it again.

No comment yet, add your voice below!