Choosing the Right Inflatable Seal: A Guide for Engineers and Designers

Introduction

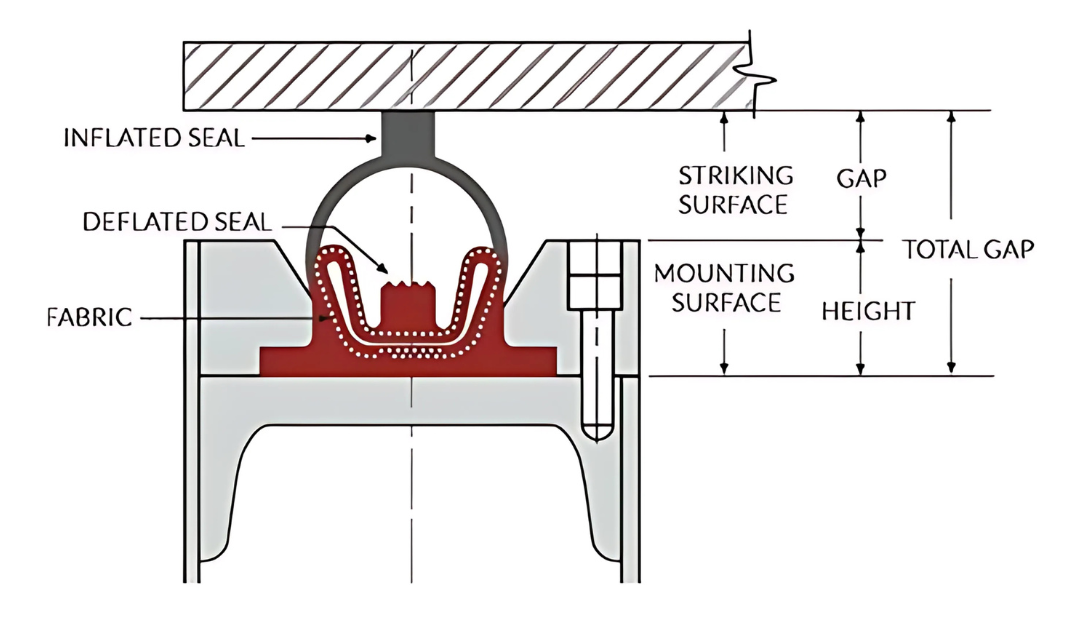

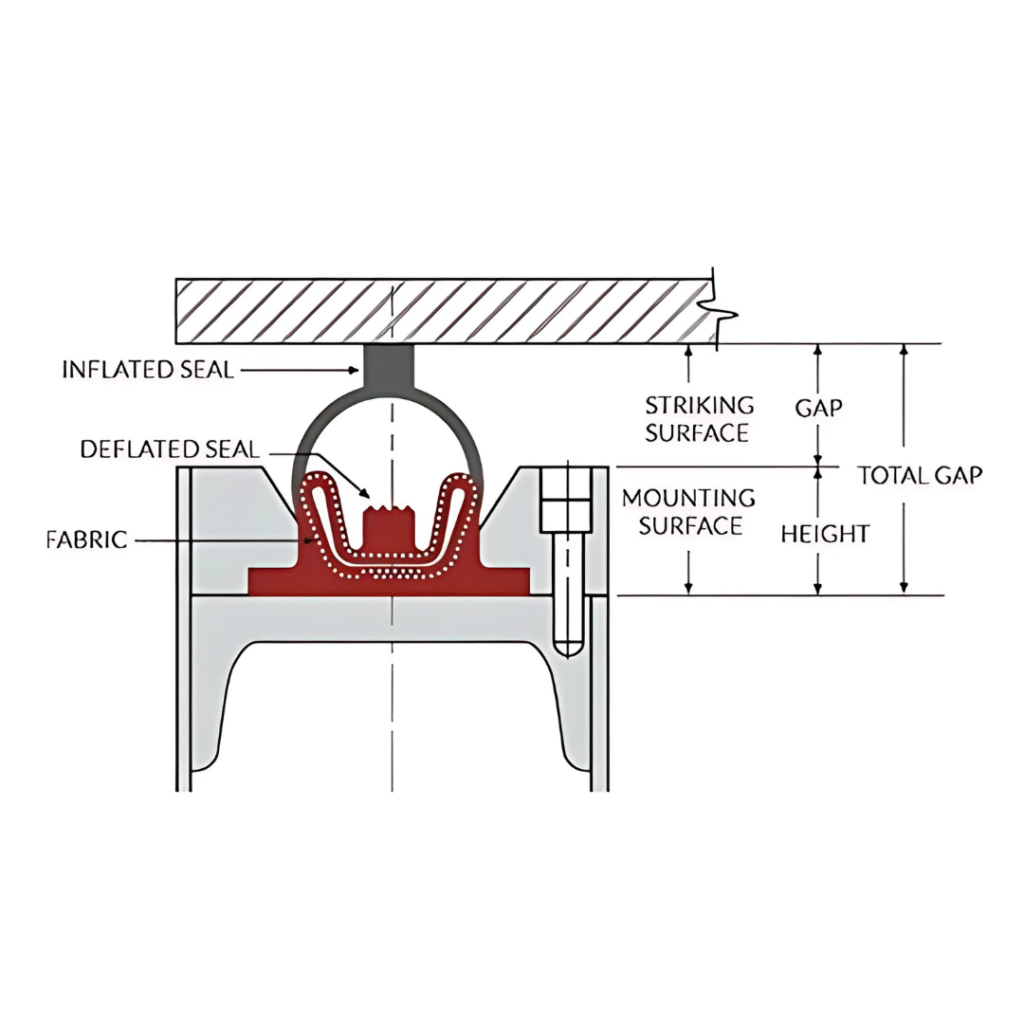

Understanding Inflatable Seals

Choosing the Right Inflatable Seal

1. Define Your Application Needs

2. Picking the Right Material

- Silicone: Renowned for its flexibility in extreme temperatures, making it ideal for medical devices and food-grade applications. Learn more about its applications here.

- EPDM (Ethylene Propylene Diene Monomer): A champion in outdoor settings due to its resistance to UV rays and ozone. Discover its benefits for outdoor use.

- Neoprene: Offers a balance of flexibility and moderate resistance to oils and chemicals—perfect for marine environments. Explore its versatility in marine settings.

- Nitrile (Buna-N): The go-to choice for oil and fuel applications in automotive and industrial machinery. Find out how it performs in automotive and industrial settings.

- Fluorosilicone: Combines the advantages of both silicone and fluorocarbon, perfect for aerospace and high-performance sealing needs. Read more about its aerospace applications.

- FKM (Viton): Known for its high resistance to chemicals and extreme temperatures, commonly used in automotive and industrial sealing. Understand its role in automotive and industrial sealing.

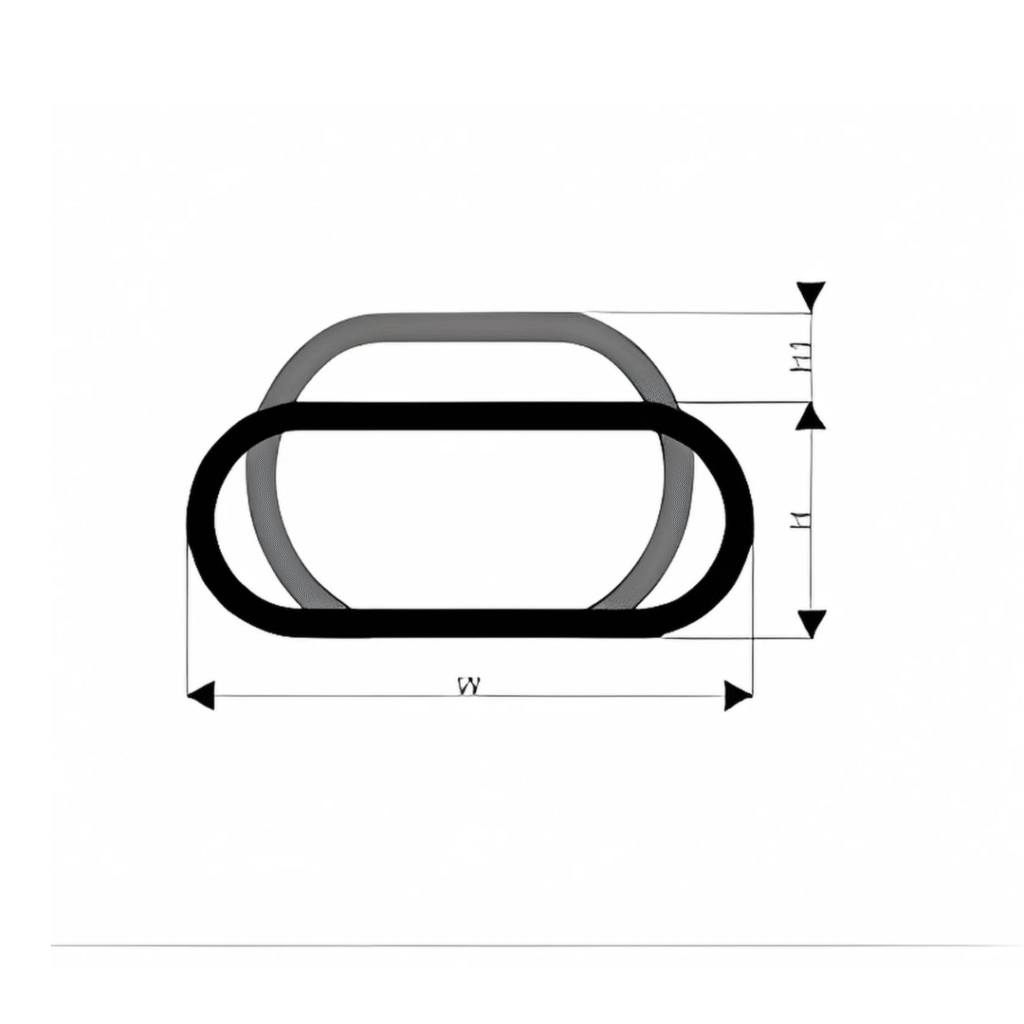

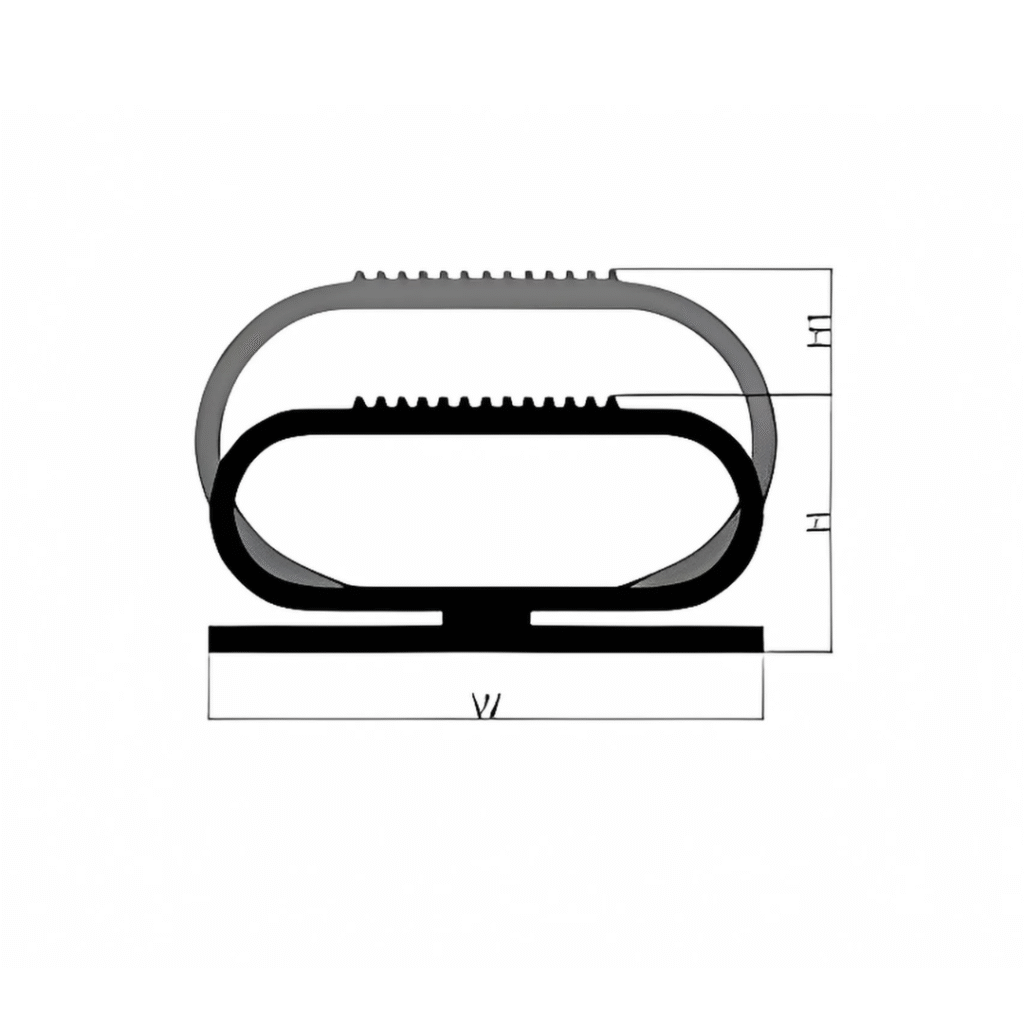

3. Selecting the Right Seal Shape

The geometry of your inflatable seal is just as critical as its material. Different shapes serve different purposes, depending on the application:

- Radial Inward Inflation: Seals that expand towards the center, commonly used in containment systems where an internal pressure lock is required.

- Radial Outward Inflation: Seals that expand outward from the center, ideal for applications requiring an external sealing force.

- Axial Inflation: Seals that expand along their length, used in applications like hatch covers and access panels.

Western Rubbers also offers various standard seal profiles, each designed for specific applications:

- Footless Seals: These seals are designed for tight spaces, easily fitting into grooves or bonding directly to surfaces for a seamless fit. Check out how they work here.

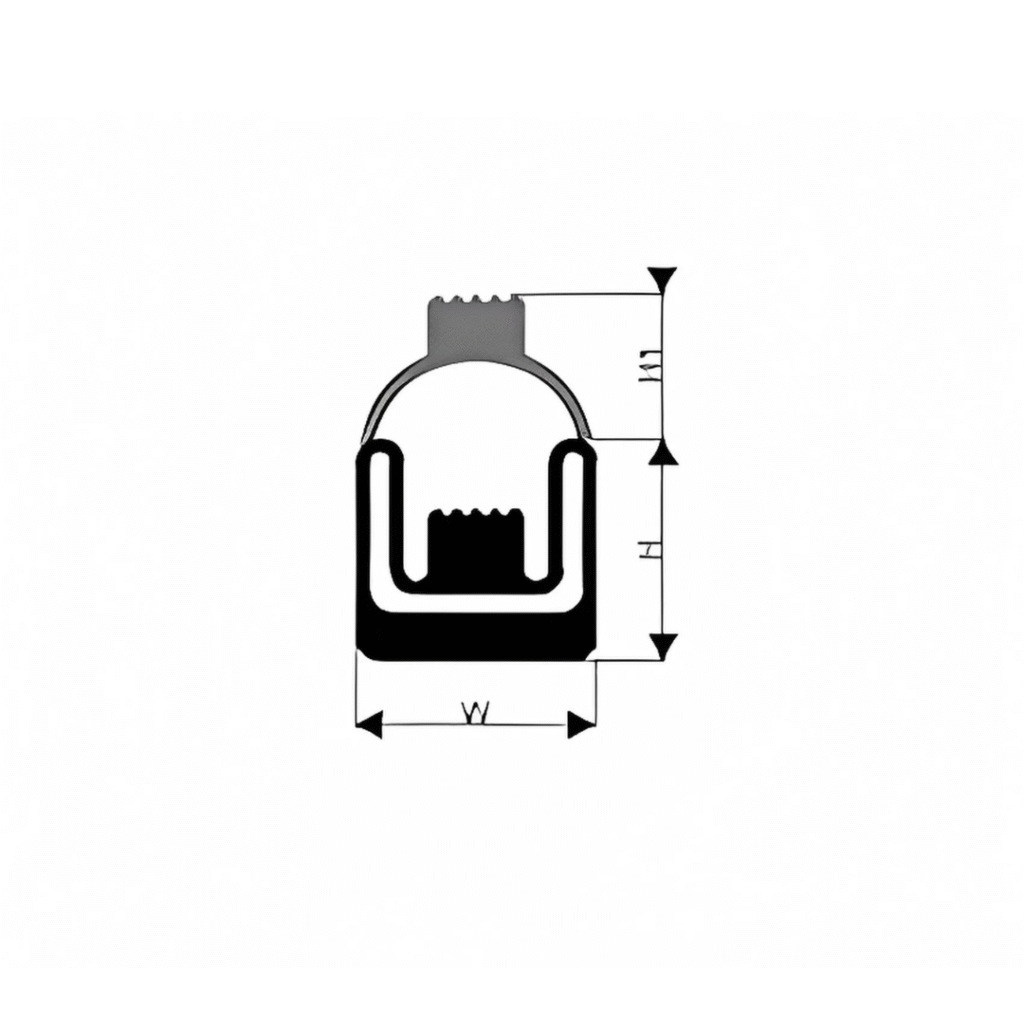

- Fasten-in Seals: With their secure fastening, these seals are great for applications where stability is key, especially in high-pressure environments. Learn more about them.

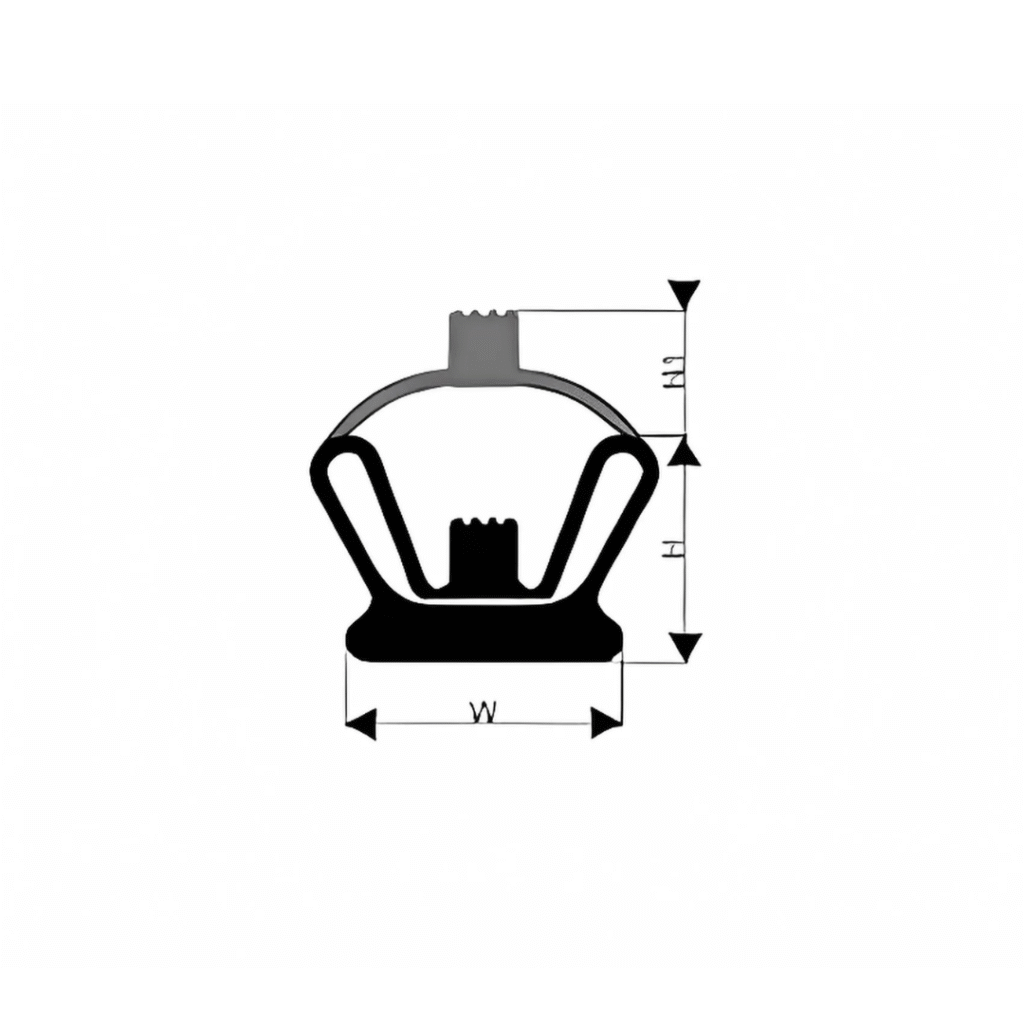

- Snap-in Seals: Easily inserted into pre-machined grooves, these seals offer a quick and hassle-free installation process, making them a great choice for time-sensitive setups. See more here.

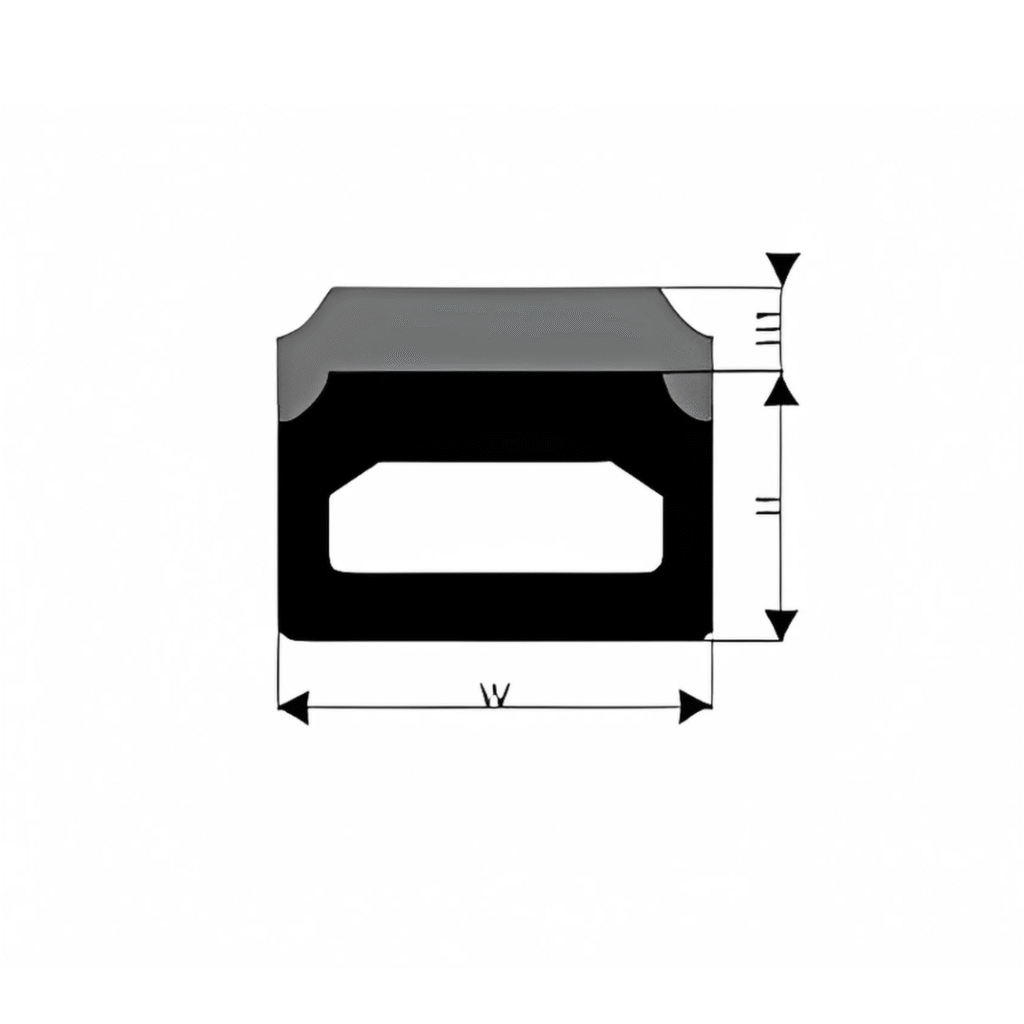

- Bonded Bottom Seals: These seals are permanently fixed to a surface, ensuring they stay in place during inflation, which makes them ideal for more demanding applications. Find out more here.

Slot Fit Seals: Designed to fit snugly into a slot or channel, these seals provide a secure and reliable seal for doors, hatches, and containment systems. Explore how they fit in.

4. Evaluating Environmental Factors

No matter how well-designed a seal is, if it can’t withstand its environment, it will ultimately fail. Consider factors like temperature fluctuations, chemical exposure, and mechanical stress:

- In high-temperature industrial ovens, heat-resistant seals are essential.

- Outdoor applications require UV resistance to prevent degradation over time.

Neglecting these environmental factors can lead to frequent replacements and increased costs. Thinking beyond just the immediate application is vital for long-term success.

5. Inflation Medium and Pressure Considerations

Inflatable seals operate using different inflation mediums—some use air while others utilize liquid or gel for added stability. Air-inflated seals are common due to their quick response times; however, liquid inflation may be preferable in high-pressure situations where stability is crucial.

Additionally, ensure that your seal can handle at least two to three times the expected load; otherwise, you risk deflation under pressure leading to gaps that can compromise functionality.

6. Installation and Fit

A fantastic seal is only as good as its installation. Proper installation ensures that the seal inflates evenly, maintains alignment, and lasts longer. An effective retaining system keeps the seal secure while allowing it to function without restriction.

In food processing plants, improperly installed seals can trap bacteria—leading not only to contamination risks but also potential product recalls.

For Better understanding watch this: Inflatable Seal – Clean Room Doors

7. Meeting Regulatory Standards

Compliance with industry standards is non-negotiable. Different sectors have stringent requirements regarding safety and performance:

- The FDA regulates materials used in food and pharmaceutical applications.

- ISO 9001 certification ensures quality management processes are in place.

- ASTM Standards outline performance expectations under real-world conditions.

Using non-compliant seals can lead to legal complications or costly recalls—so always verify compliance before making a choice.

Still Unsure? Watch How Inflatable Seals Work

If you’re more of a visual learner or want a deeper understanding of inflatable seals in action, check out this comprehensive video demonstrating their functionality: Inflatable Seal – Vibration Testing Room Door

Key Lessons for Long-Lasting Seal Efficiency

Choosing the right inflatable seal isn’t just about picking a random rubber tube—it’s about ensuring durability, efficiency, and safety in your application.

By carefully considering the environment, material, shape, pressure requirements, and compliance standards, you can make a well-informed decision that prevents costly failures and enhances system performance.

Need expert guidance? Reach out today for personalized recommendations!

📩 Get in touch or email us at sales@westernrubbers.com to discuss your mold

development needs.

[Suggested Internal Links]:

Want to know more about who we are and what drives our innovation?

👉 About Western Rubbers

No comment yet, add your voice below!