our products

Inflatable Seals

Introduction

Inflatable Seals

Features

Products Benefits

Asia’s largest and fastest manufacturer of inflatable seals

Inflatable seals with 6 month warranty certification

Design guidance for customized seals

Classification

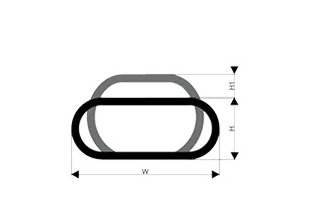

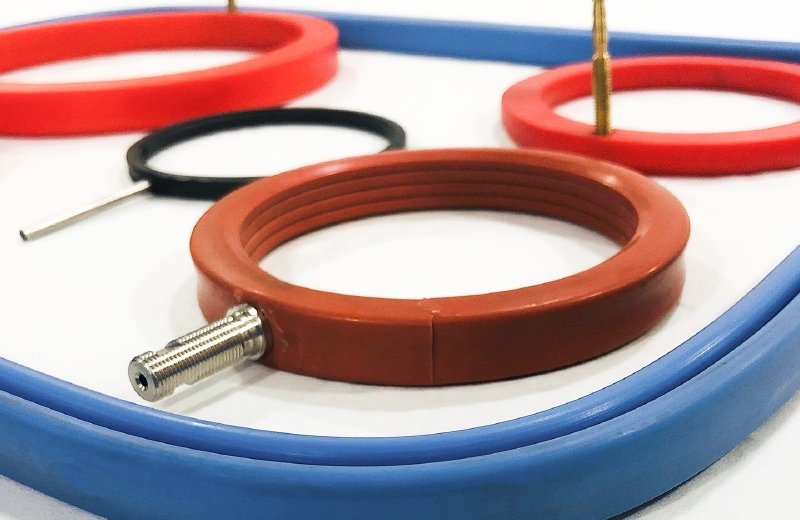

Non-Reinforced Inflatable Seals

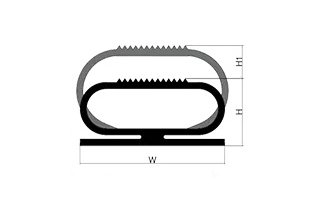

Fabric Reinforced Inflatable Seals

- NYLONTM

- DACRONTM

- NOMEXTM

- KEVLARTM

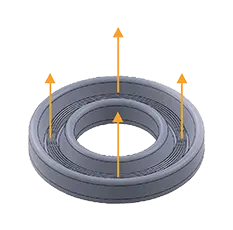

Axial

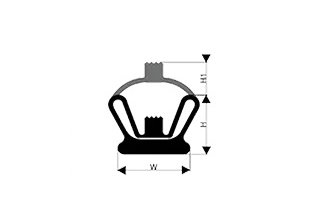

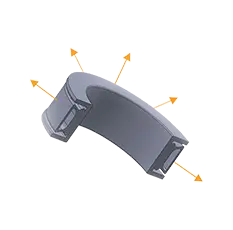

Radial-Outward

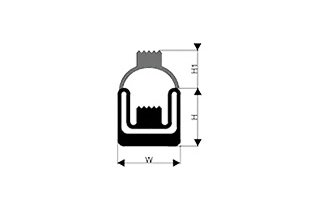

Radial-Inward

Inflatable seals with small outside diameters may end up wrinkling with this kind of expansion. Seals expanding radially inward have Air Inlet Valves(AIV) typically installed into a channel with the outside diameter (OD).

Circular

Circular seals are mostly preferred for sealing manhole covers, hopper seals or in industrial machinery like fluidized bed dryers & autoclaves; wherein the machines are made in circular dimensions.

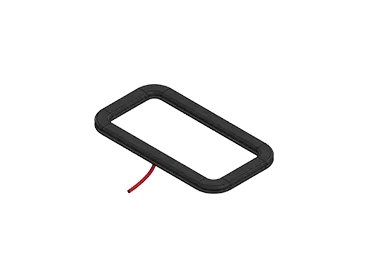

Rectangular

Straight

Inflatable seals with straight configurations are most commonly found in clamps and actuators. Straight seals have vulcanized ends that do not expand. Western Rubbers’ also provides retention mechanisms for straight seals.

U shaped

U shaped seals are a common configuration in inflatable gate seals. Ends of u-shaped seals are vulcanized & hence cannot inflate. Appropriate retention mechanisms for this configuration is available at Western Rubbers.

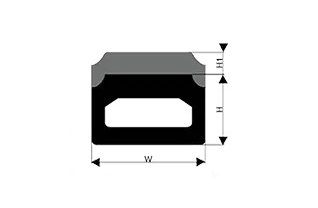

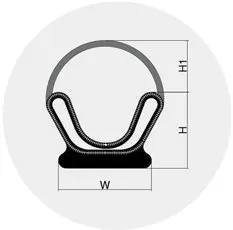

standard Dimensions

Inflatable Seals Profile

Our use Cases

Applications

Inflatable Seal for Robotic Automation Systems

Inflatable seals revolutionize robotic clamping systems, offering unparalleled precision and versatility in automation processes. These innovative seals expand uniformly, providing a secure grip on diverse surfaces while minimizing the risk of component damage. Their adaptive nature allows for seamless handling of irregular or delicate items, expanding the capabilities of automated systems.

Gas Tight Inflatable Door Seal for Hazardous Facilities

Inflatable rubber seals offer an effective and secure solution for gas-tight door sealing in hazardous facilities. Incorporating inflatable seals in gas-tight doors enhances safety and regulatory compliance, making them essential in laboratories, chemical plants, and other hazardous environments.

Low Smoke Silicone Inflatable Seals for Trains

Custom Made EPDM and Silicone Inflatable Seals for Rail and Mass Transit industry that are tested to stringent norms of EN 45545 , UL V0, FMVSS and other such fire safety standards.

Fabric Reinforced EPDM Inflatable seal for Nuclear Power Plants

Western Rubbers Inflatable Seals manufactured for the nuclear facility are radiation tested. Designed to be resilient to radiation ensure leak proof sealing in extrement conditions .

USP class Vl Inflatable Seal for Pharmaceutical Equipments

Silicone Inflatable Seals for Medical and Phamaceutical application meets US FDA, USP CLASS Vl and EU pharmacopoeia requirements. Some of the applications included Fludised Bed Dryers/processors, Glove box Isolators, Tablet Coater, Clean Room Doors, Laboratory Automation Equipments.

Semiconductor Equipment Inflatable Seals

Inflatable Seals for the semiconductor industry are designed with fabric reinforced for vey high cycle life. These are specifically packed in clean room enviroments for highly critical semiconductor manufacturing facilities. These inflatable seals are used in Lithography Equipment , Load lock equipments, CVD/ PEVD equipment seal, Fabrication Units, Etching, Deposition and Implantation equipments.

Inflatable Seals for Aerospace and Defence

These custom made large fabric reinforced seals are designed with extreme temperature and moisture condition encountered in aerospace applications. Seals are made from Silicone and Flurosilicone for high durability and performance Some applications include Canopy of figter jets, Door Hanger seals, Passenger aircraft door seal, satellite transportation container seals.

Inflatable Seals for Marine Applications

Inflatable Seals for Marine applications have custom compounds of EPDM and Neoprene keeping in mind the highly Saline and Corrosive enviroment of the Sea. Inflatable Seals are made fo Hatches and Doors, Superyachts, propellor shafts, Sub sea equipments.

Inflatable Seals for Bulk Material Handling

Bulk Material Handling Inflatable seals have high abrasion resistance to increase performance and seal like especially for highly abrasive applications like Bulk Bag Filling and Drum Filling. Major OEMs have also started to switch from standard inflatable seals to Fabric Reinforced Seals longer cycle like reducing their equipment downtime .

Inflatable Seals for Critical Doors

Seperate Page ( nuclear power plant, Gas tight doors, Satellite Vibration testing facility, Jet Propulsion Lab Doors.

Inflatable Seals for Vaccuum Impregnation Equipments

Automotive and critical engineering castings need a specialised impregnation treatment to ensure no porosi ty or failure of the castings. These opertations are carried out in Vacuum conditions needing Inflatable Seals to ensure air tight sealing

Design Guidance

Design Guidance | Purpose |

|---|---|

Need More Details? Refer To The Blog | Need Design Guidance? Schedule a call with our expert |

Environment | Select rubber compatible with temperature and fluids in contact |

Expected Life | Choose between fabric or non-fabric seals based on durability needs |

Pressure Differential | Select fabric or non-fabric seals based on pressure conditions |

Inflation Gap | Choose the correct seal profile based on the required inflation gap |

Equipment Design | Determine corner radius (if applicable) and inflation type (Radial In/Out) |

Air Connector | Ensure easy installation and removal of the seal |

Retention Mechanism | Secure the seal to prevent displacement during operation |

Safety Systems | Prevent over-pressurization to avoid seal failure |

Types of Rubber for Inflatable Seals

MAterial | Temperature Range | Strengths | Limitations |

|---|---|---|---|

EPDM | -50°C to 150°C | Excellent aging, ozone, weather resistance; Flexible at low temperatures | Poor resistance to petroleum oils, acids, and bases |

Neoprene | -40°C to 125°C | Good weather and ozone resistance; Moderate oil resistance; Flame

resistant | Not suitable for strong acids, esters, or gasoline |

NBR | -40°C to 120°C | High resistance to oils and fuels; Good abrasion resistance | Poor resistance to ozone, sunlight, and weathering |

HNBR | -40°C to 165°C | Exceptional oil/fuel resistance; Superior mechanical properties | Higher cost; Limited resistance to strong acids and bases |

Natural Rubber (NR) | -50°C to 80°C | High resilience, flexibility; Good adhesion to metals | Poor resistance to oils, ozone, weathering; Limited

temperature stability |

Silicone (MVQ) | -60°C to 230°C | Excellent temperature resistance; Good weather and UV resistance | Poor resistance to oils, acids; Lower tensile strength |

Fluorosilicone (FVMQ) | -60°C to 200°C | Excellent resistance to oils and solvents; Wide temperature range | Higher cost; Lower mechanical properties than silicone |

FKM (Viton) | -20°C to 200°C | Superior chemical resistance; Excellent high-temp stability | Poor low-temperature performance; Higher cost |

Ask Me

Frequently Asked Questions

Inflating Radially Inward Seals:

Seals that inflate in the direction of the radius i.e. towards the center

Inflating Radially Outward Seals:

Seals that inflate in the direction of the circumference i.e. away from the center

Inflating Face Seals:

Seals that inflate perpendicular to the seating surface.

Generally, for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your design pressure requirements are higher than 7-8 Bar then we suggest customers to go for fabric reinforced seals for longer life and effective functionality.

We use Kevlar, Nylon, Nomex, Polypropylene and Dacron.

We can manufacture both kinds of inflatable seals; ones which require continuous air supply or

those seals which can work with a one-time fill, like a tire tube.

We can manufacture inflatable seals that can withstand temperatures up to 250 degrees (use symbol) Celsius (480 degrees F).

Western Rubbers can manufacture seals that can withstand pressures up to 30 Bar.

EPDM, Viton, Neoprene, Silicone, Nitrile and Natural rubber can be used for manufacturing

inflatable seals.

For longer life of the inflatable seal, the inflation gap between the striking surface of the seal and the mating surface should be between 5-8 mm.

Yes, we assist clients right from the designing stage to the testing and installation stage of the inflatable seal.

Yes, we manufacture FDA compliant inflatable seals. Our seals pass the stringent tests of US FDA and EU pharmacopoeia. We also provide all major food and pharmaceutical grade certifications on request.

We provide Mullen burst test report, underwater leak test report, compound report and

cycle test report (on request).